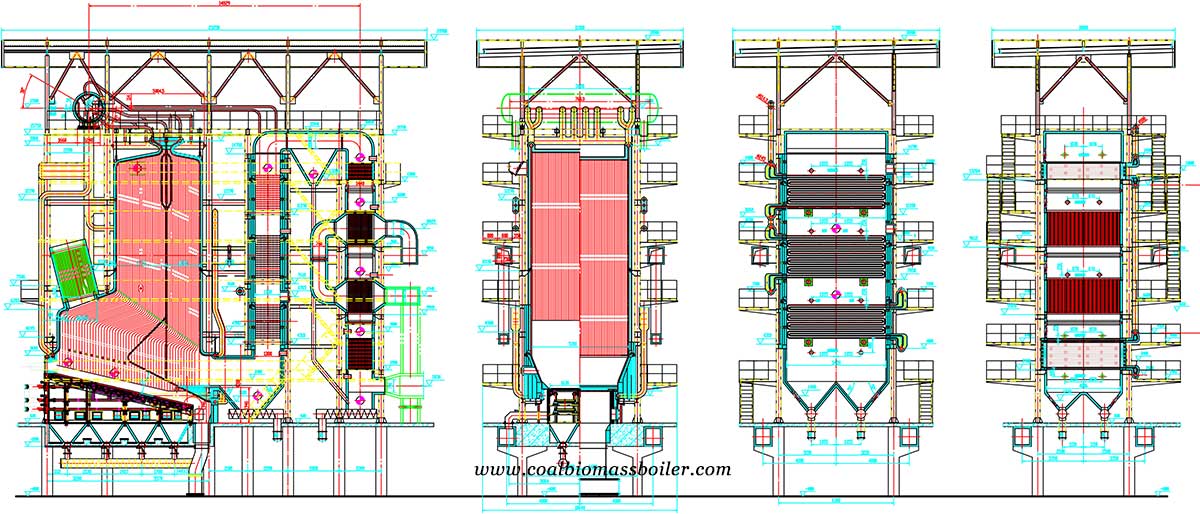

Biomass boiler of DHW series (also called DHW biomass boiler) is the kind of single drum horizontal biomass fired boiler with inclined reciprocating grate, its reciprocating grate’s inclination angle is 15 degrees. The furnace is membrane wall structure, furnace outlet has slag-cooling tubes and furnace outlet flue gas temp is lower than the melting point of fly ash which is below 800℃, so it can prevent the fly ash from slagging on the superheater. After the slag-cooling tubes, there are high-temperature superheater, low-temperature superheater, economizer and air preheater, there is spray type desuperheater between two superheaters. The flue gas temperature after air preheater is 160℃.

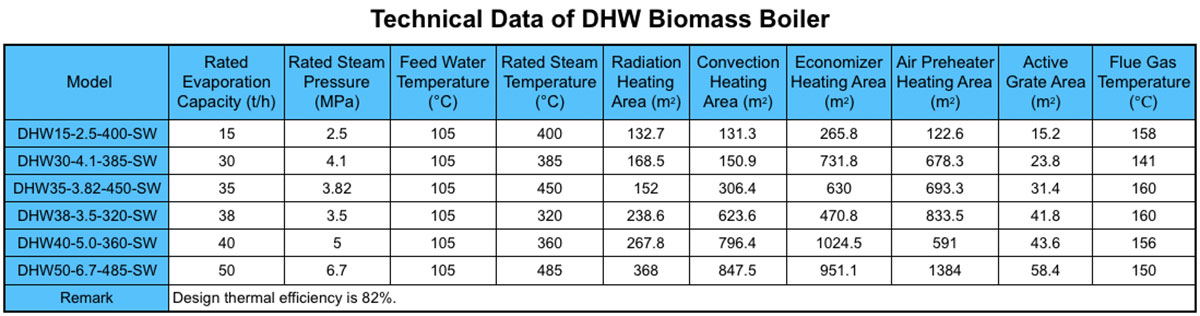

DHW series biomass boiler can generate low pressure steam with rated evaporation capacity of 10-65 tons/h and rated pressure of 1.25-9.8 MPa. The designed thermal efficiency is up to 82%.

Technical Data of DHW Biomass Boiler

DHW Biomass Boiler Features

- Since biomass fuel is apt to slagging, reciprocating grate’s ceaseless movement avoids slagging.

- Biomass fuel features small density and small ash particle, which is apt to flow with the flue gas, so we design high furnace and small flow velocity.

- Secondary air ensures that the fuel’s standing time in the furnace makes the fuel burn out in the furnace.

- The arch is used to strengthen the mixture of airflow in the furnace and organize the thermal radiation and hot flue gas flow in the furnace.

- To avoid soot formation, the pitch of convection heating surface shall be in-line arrangement.

- The convection bank has acoustic wave soot blower, which may remove the soot, and cleaning door is equipped.

DHW Biomass Boiler Applications

As one of the largest industrial boiler manufacturers in the world, TAISHAN Group had been deigning, fabricating and installing turn key biomass boilers domestic and abroad since 2007. Our Biomass Boiler Systems like biomass steam boiler, biomass hot water boiler can provide successful strategies and technology which can reduce the operational costs of current facilities and provide better ROI from newly reinstalled biomass fired boiler systems.

DHW series biomass boilers are widely used in chemical industry, paper making industry, textile industry, food industry, pharmaceuticals industry, heating industry and construction industry, etc al.

About TAISHAN Group

As the National Hi-tech Enterprise certificated by the government and the 500 Largest Machinery Industrial Enterprises, Taishan Group had been dedicated in supplying turn key coal fired boiler and industrial boiler solutions to worldwide customers since in 1994. We have 4,300 employees, 1.02 million square meters factory with 0.6 billion dollars assets. Taishan Group is in the leading position by passing Class A Manufacture License of boiler, Class A1, A2 & A3 Design and Manufacture License of pressure vessel, Installation License of Class I boiler and various pressure vessel, ISO9001, ISO14001, OHSAS18001, ASME and PCCC certification. We had provided many types of effective and states of the art coal fired boilers, biomass boilers and other industrial boilers, pressure vessels, transformers and other related products to over 36 countries since its foundation in 1994.

TAISHAN Group is not only manufacturing best quality coal fired boiler and biomass boiler products but also providing custom product design, fabrication and after-sale service. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.