What Is an Industrial Oil-Fired Boiler and How Does It Work?

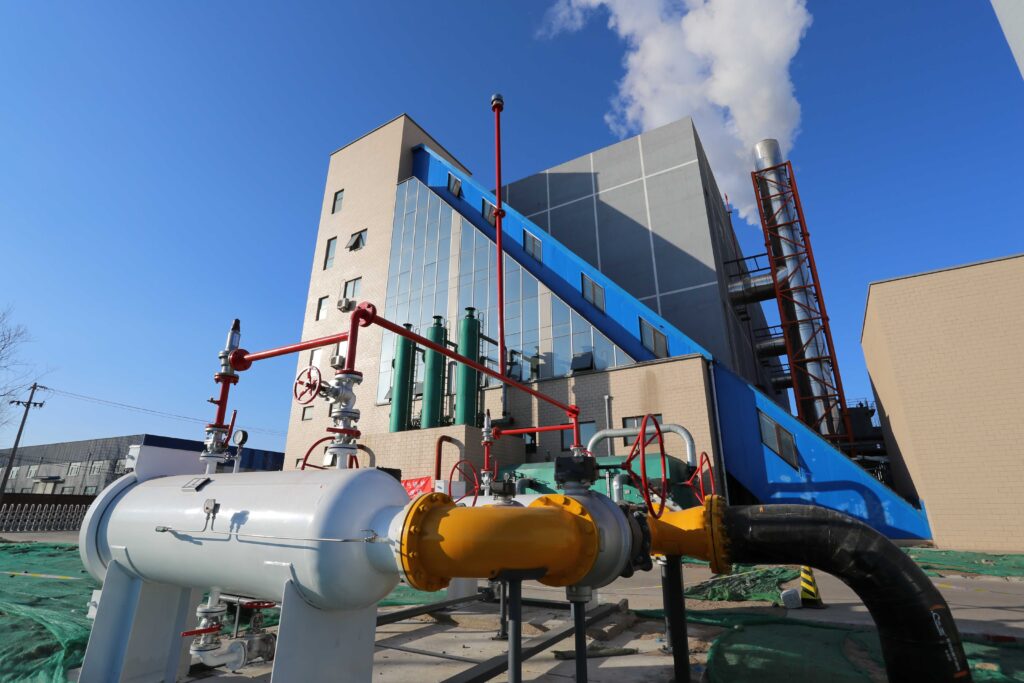

Industrial facilities often require high-efficiency and reliable heating solutions, especially in regions where natural gas is unavailable or costly. However, many businesses face challenges such as fuel efficiency concerns, maintenance requirements, and emission regulations when using oil-fired boilers. Without a clear understanding of how these systems operate, companies risk increased fuel consumption, higher operational costs, and potential compliance issues. The key to overcoming these challenges lies in understanding the fundamental working principles of industrial oil-fired boilers and how to optimize their performance.

An industrial oil-fired boiler is a large-scale heating system that burns fuel oil to produce steam or hot water for industrial applications. The process begins with oil being pumped from a storage tank into the burner, where it is atomized and ignited. The heat generated is transferred to water via heat exchanger tubes, producing steam or hot water for manufacturing, power generation, or other industrial processes. Key components include the burner, combustion chamber, heat exchanger, fuel supply system, exhaust system, and control panel. Modern oil-fired boilers integrate advanced combustion technologies to enhance efficiency, minimize emissions, and reduce operational costs.

To maximize performance, industries must understand the inner workings of these boilers, the types of fuel used, and the technologies that improve efficiency. Let’s explore these aspects in detail.

What Are the Main Components of an Industrial Oil-Fired Boiler?

Industrial oil-fired boilers are used in power generation, manufacturing, chemical processing, and heating applications. They operate by burning heating oil, diesel, or heavy fuel oil (HFO) to generate high-temperature steam or hot water. To ensure efficient and reliable operation, these boilers consist of several critical components that work together to control fuel combustion, heat transfer, and exhaust management.

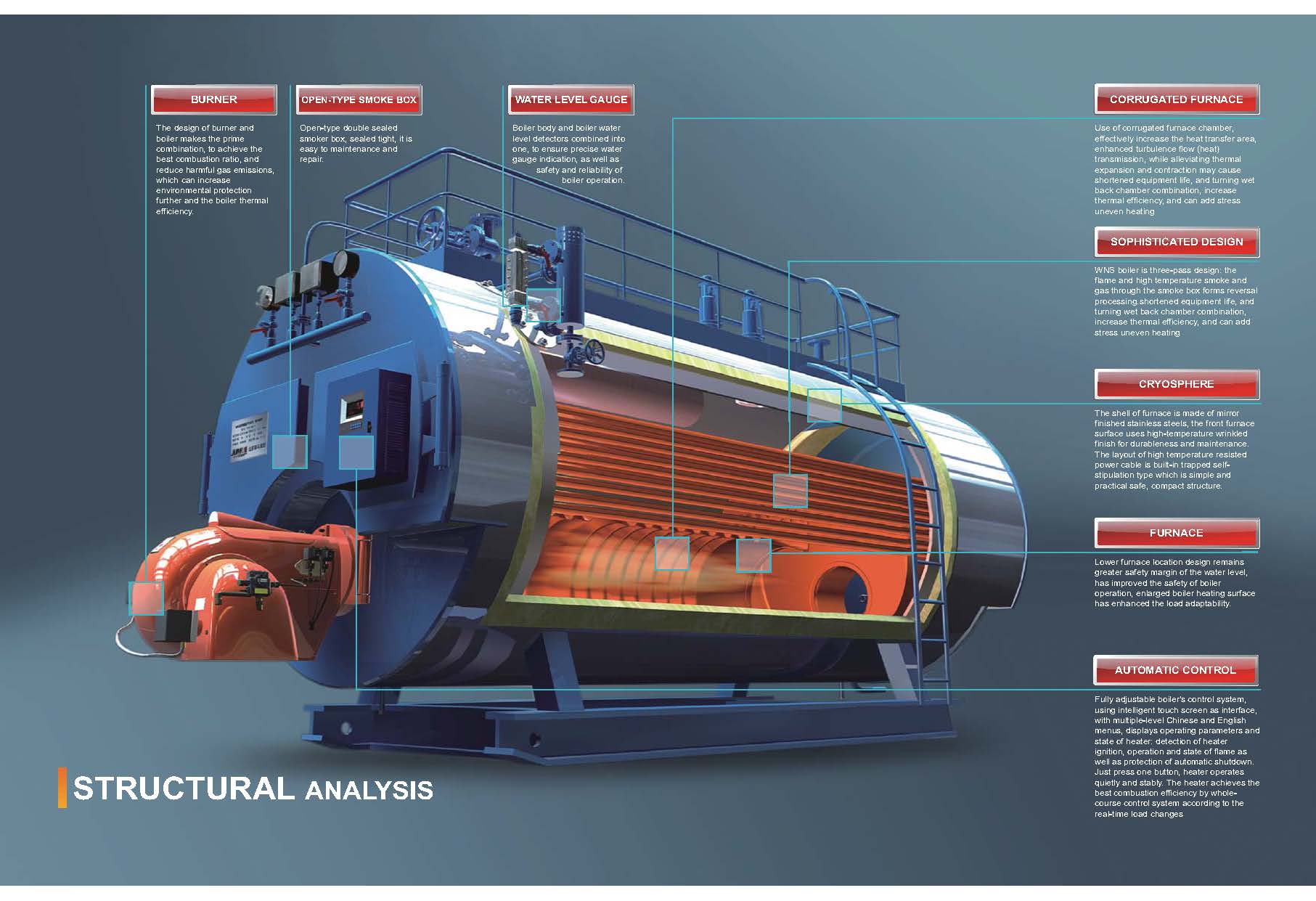

The main components of an industrial oil-fired boiler include the burner, combustion chamber, heat exchanger, fuel supply system, air supply system, flue gas system, water circulation system, and control system. Each component plays a vital role in ensuring efficient fuel combustion, optimal heat transfer, and emission control.

Understanding these components helps optimize efficiency, improve safety, and extend the lifespan of the boiler, ensuring reliable industrial operations.

Industrial oil-fired boilers do not require a burner.False

The burner is a crucial component of an oil-fired boiler, as it controls fuel atomization and combustion efficiency.

1. Burner System

The burner is the core component of an oil-fired boiler, responsible for fuel atomization and ignition. It mixes fuel with air and ignites it to create a controlled combustion process.

Key Features of the Burner System

- Fuel atomization breaks liquid fuel into fine droplets for efficient burning.

- Air-fuel mixing ensures proper oxygen supply for complete combustion.

- Flame stabilization controls the flame shape and stability to maximize heat output.

Types of Burners Used in Oil-Fired Boilers

| Burner Type | Fuel Atomization Method | Common Applications |

|---|---|---|

| Pressure Jet Burner | High-pressure fuel injection | Power plants, industrial heating |

| Rotary Cup Burner | Spinning cup for fine fuel mist | Heavy fuel oil applications |

| Air Atomizing Burner | Uses compressed air for atomization | High-efficiency steam boilers |

A well-maintained burner improves combustion efficiency, reduces fuel waste, and lowers emissions.

2. Combustion Chamber

The combustion chamber is where fuel combustion occurs, generating high-temperature heat that is transferred to the boiler’s heat exchanger.

Key Functions of the Combustion Chamber

- Provides a stable environment for fuel combustion.

- Contains refractory linings to withstand high temperatures.

- Optimizes heat absorption and flame retention.

| Combustion Chamber Feature | Purpose |

|---|---|

| Refractory lining | Protects against extreme heat |

| Fire tubes or water tubes | Transfers heat to boiler water |

| Insulated walls | Minimizes heat loss |

A well-designed combustion chamber enhances fuel efficiency and reduces unburned fuel residues.

3. Heat Exchanger

The heat exchanger transfers heat from combustion gases to water or steam, maximizing energy efficiency.

Types of Heat Exchangers in Oil-Fired Boilers

| Heat Exchanger Type | Function | Common Applications |

|---|---|---|

| Fire-Tube Boiler | Hot gases pass through tubes submerged in water | Low-pressure steam applications |

| Water-Tube Boiler | Water flows inside tubes heated by combustion gases | High-pressure steam power plants |

| Coil-Type Boiler | Compact design with rapid heating | Instant hot water systems |

Efficient heat exchangers improve fuel utilization and reduce operating costs.

4. Fuel Supply System

The fuel supply system ensures a continuous and controlled flow of oil to the burner, maintaining stable combustion.

Main Components of the Fuel System

- Fuel storage tank stores diesel, heating oil, or heavy fuel oil.

- Fuel pump delivers oil to the burner at the correct pressure.

- Oil filter removes impurities to prevent clogging.

- Fuel preheater (for heavy fuel oil) reduces viscosity for better atomization.

| Fuel Type | Preheating Requirement | Usage |

|---|---|---|

| Diesel (Light Oil) | No preheating needed | Small to medium boilers |

| Heavy Fuel Oil (HFO) | Requires preheating | Large industrial boilers |

A properly maintained fuel system ensures smooth burner operation and reduces fuel wastage.

5. Air Supply System

Air is essential for complete combustion, and the air supply system ensures the correct air-to-fuel ratio.

Main Components of the Air Supply System

- Blower fan supplies oxygen-rich air for combustion.

- Dampers and louvers regulate airflow to the burner.

- Preheated air system improves combustion efficiency and fuel burn rate.

| Air System Feature | Function |

|---|---|

| Forced Draft Fan | Pushes air into the burner for stable combustion |

| Induced Draft Fan | Controls exhaust gas flow to maintain efficiency |

| Air Preheater | Warms incoming air to increase fuel efficiency |

Optimized air supply reduces fuel consumption and minimizes emissions.

6. Flue Gas System and Emission Control

The flue gas system removes combustion gases and ensures compliance with emission regulations.

Main Components of the Flue Gas System

- Flue gas economizer recovers heat from exhaust gases.

- Chimney stack safely vents gases away from the facility.

- Electrostatic precipitator (ESP) captures fine particulate matter.

- Scrubber or catalytic converter reduces NOx, SOx, and CO emissions.

| Pollutant | Control Method |

|---|---|

| Particulate matter | Electrostatic precipitators (ESP) |

| Sulfur dioxide (SO2) | Flue gas desulfurization (FGD) |

| Nitrogen oxides (NOx) | Low-NOx burners, selective catalytic reduction (SCR) |

Effective flue gas treatment reduces environmental impact and regulatory penalties.

7. Water Circulation System

Water circulation ensures even heat distribution and prevents overheating or pressure fluctuations.

Main Components of the Water System

- Feedwater pump supplies water to the boiler under high pressure.

- Steam drum (for water-tube boilers) separates steam from water.

- Blowdown system removes impurities to prevent scaling.

| Water Treatment Process | Purpose |

|---|---|

| Softening | Removes calcium and magnesium to prevent scaling |

| Deaeration | Eliminates oxygen to reduce corrosion |

| Blowdown | Removes sludge and concentrated impurities |

Proper water treatment increases boiler lifespan and reduces maintenance costs.

8. Control and Automation System

The control system regulates fuel input, combustion, pressure, and temperature for optimal performance.

Key Features of Boiler Control Systems

- Automated fuel and air ratio adjustment enhances efficiency.

- Real-time pressure and temperature monitoring prevents overheating.

- Emergency shutdown and safety interlocks ensure safe operation.

| Control Feature | Function |

|---|---|

| Pressure controls | Maintain safe steam levels |

| Flame sensors | Detect flame stability |

| Remote monitoring | Allows automated adjustments |

Advanced automation improves efficiency, reduces fuel waste, and enhances safety.

How Does the Combustion Process Work in an Industrial Oil-Fired Boiler?

Industrial oil-fired boilers are widely used in power generation, manufacturing, chemical processing, and heating applications. They burn liquid fuels such as diesel, heavy fuel oil (HFO), or kerosene to generate heat, which is then transferred to water or steam for industrial use. The combustion process in an oil-fired boiler is carefully controlled to maximize energy efficiency, reduce emissions, and ensure operational safety.

The combustion process in an industrial oil-fired boiler involves fuel atomization, air mixing, ignition, flame stabilization, heat transfer, and flue gas management. The burner atomizes liquid fuel into fine droplets, mixes it with air, and ignites it to create a controlled flame, which transfers heat to the boiler water while ensuring efficient combustion and minimal emissions.

Understanding the combustion process helps optimize boiler efficiency, reduce fuel consumption, and lower environmental impact.

Oil-fired boilers can operate without an air supply.False

Air is essential for the combustion process, as it provides the oxygen needed for fuel to burn efficiently.

1. Fuel Atomization and Injection

The first step in the combustion process is breaking liquid fuel into fine droplets through atomization.

How Atomization Works:

- The oil pump pressurizes fuel and sends it to the burner.

- The nozzle converts pressurized fuel into a fine mist.

- In pressure jet burners, high fuel pressure forces oil through the nozzle at high velocity.

- In air atomizing burners, compressed air or steam assists in breaking fuel into smaller droplets.

| Atomization Type | Fuel Efficiency | Common Application |

|---|---|---|

| Mechanical Atomization | Moderate | Standard industrial boilers |

| Air Atomization | High | High-efficiency systems |

| Steam Atomization | High | Large heavy fuel oil (HFO) boilers |

Fine atomization ensures complete combustion and reduces unburned fuel residues.

2. Air-Fuel Mixing

For efficient combustion, fuel droplets must mix with the correct amount of oxygen. The air supply system provides oxygen for combustion.

Components Involved in Air-Fuel Mixing:

- Forced draft fan: Pushes fresh air into the burner.

- Air register: Regulates airflow and controls mixing with fuel mist.

- Swirl vanes & baffles: Improve fuel-air mixing efficiency.

| Air-to-Fuel Ratio | Combustion Efficiency | Impact |

|---|---|---|

| Too Low | Incomplete combustion | High CO & soot formation |

| Optimal | Maximum efficiency | Low emissions & high heat transfer |

| Too High | Excess air cooling effect | Reduced efficiency & high NOx emissions |

Balanced air-fuel mixing optimizes combustion efficiency and minimizes pollutants.

3. Ignition and Flame Stabilization

Once the air-fuel mixture is formed, it is ignited to generate a stable flame inside the combustion chamber.

How Ignition Occurs:

- Pilot flame or spark ignition system ignites the fuel-air mixture.

- Flame detectors and sensors ensure continuous flame presence.

- Flame shape & stability are controlled by burner design.

| Flame Condition | Efficiency | Potential Issue |

|---|---|---|

| Short & bright | High efficiency | Optimal combustion |

| Long & lazy | Low efficiency | Incomplete combustion, soot formation |

| Unstable flame | Low efficiency | Possible burner failure |

A properly stabilized flame ensures consistent heat transfer and safe boiler operation.

4. Heat Transfer to Boiler Water

The combustion flame heats the boiler’s heat exchanger, transferring energy to water or steam.

Heat Transfer Mechanisms:

- Radiation: Direct heat transfer from the flame to water tubes.

- Convection: Hot gases circulate, transferring heat to water or steam.

- Conduction: Metal tubes conduct heat to the working fluid.

| Heat Exchanger Type | Heat Transfer Efficiency | Common Applications |

|---|---|---|

| Fire-Tube Boiler | Moderate | Low-pressure steam applications |

| Water-Tube Boiler | High | High-pressure steam power plants |

| Economizer System | Very High | Waste heat recovery |

Efficient heat transfer reduces fuel consumption and operational costs.

5. Flue Gas Management and Emission Control

After combustion, flue gases exit through the chimney stack, passing through pollution control systems.

Emission Control Strategies:

- Electrostatic precipitators (ESP): Remove fine particulates.

- Flue gas desulfurization (FGD): Reduces SO₂ emissions.

- Low-NOx burners & SCR systems: Minimize NOx emissions.

| Flue Gas Component | Environmental Impact | Control Method |

|---|---|---|

| Particulate Matter (PM) | Air pollution | ESP & bag filters |

| Sulfur Dioxide (SO₂) | Acid rain formation | Flue gas desulfurization (FGD) |

| Nitrogen Oxides (NOx) | Smog formation | Selective Catalytic Reduction (SCR) |

Proper flue gas management ensures compliance with environmental regulations and reduces pollution.

6. Boiler Control and Optimization

Modern automation and control systems regulate the combustion process, ensuring safe and efficient operation.

Key Control System Features:

- Fuel flow monitoring adjusts oil supply for optimal combustion.

- Airflow sensors regulate oxygen input to maintain efficiency.

- Flame monitoring detects combustion quality and prevents flameout.

| Control Feature | Function |

|---|---|

| Oxygen Trim Control | Adjusts airflow for complete combustion |

| Fuel Flow Regulation | Matches fuel input with heat demand |

| Remote Monitoring | Allows real-time combustion optimization |

Advanced control systems reduce fuel waste, lower emissions, and enhance boiler safety.

What Types of Fuel Oil Are Used in Industrial Oil-Fired Boilers?

Industrial oil-fired boilers use a variety of fuel oils to generate heat for manufacturing, power generation, and other industrial processes. The choice of fuel oil depends on factors such as availability, cost, energy content, viscosity, and emissions regulations. Selecting the right fuel oil improves efficiency, reduces maintenance costs, and minimizes environmental impact.

The main types of fuel oil used in industrial oil-fired boilers include Light Fuel Oil (LFO), Heavy Fuel Oil (HFO), Marine Fuel Oils, and specialized blends such as biodiesel. Each type has different properties, energy content, and applications, affecting combustion efficiency, emissions, and operational costs.

Understanding fuel oil types helps industries optimize boiler performance while complying with environmental regulations.

Heavy fuel oil can be used in all industrial boilers without preheating.False

Heavy fuel oil (HFO) requires preheating before combustion due to its high viscosity and low volatility.

1. Classification of Fuel Oils for Industrial Boilers

Fuel oils are categorized based on their viscosity, sulfur content, and boiling point.

| Fuel Oil Type | Viscosity (cSt at 50°C) | Sulfur Content (%) | Heating Value (MJ/kg) | Common Applications |

|---|---|---|---|---|

| Light Fuel Oil (LFO) | 1-5 | <0.1 | 42-44 | Industrial heating, small boilers |

| Heavy Fuel Oil (HFO) | 30-700 | 1.0-3.5 | 38-42 | Large industrial boilers, power plants |

| Marine Diesel Oil (MDO) | 5-11 | <0.5 | 42-44 | Ships, backup power generators |

| Biodiesel | 4-6 | <0.1 | 37-42 | Renewable energy, hybrid systems |

The selection of fuel oil depends on boiler design, fuel storage systems, and emission control requirements.

2. Light Fuel Oil (LFO)

Light fuel oil (LFO), also known as distillate fuel or diesel oil, is a low-viscosity fuel commonly used in industrial boilers.

Key Features of LFO:

- Low sulfur content (0.01%-0.1%) reduces emissions.

- High volatility allows easy ignition and efficient combustion.

- Minimal preheating required, making it ideal for quick start-up boilers.

| LFO Advantages | LFO Disadvantages |

|---|---|

| Low maintenance | Higher cost than HFO |

| Suitable for small-to-medium boilers | Limited availability in some regions |

| Meets strict emission standards | Lower energy content than HFO |

LFO is widely used in food processing, chemical industries, and district heating applications.

3. Heavy Fuel Oil (HFO)

Heavy fuel oil (HFO) is a residual oil derived from crude oil refining. It has a high viscosity and requires preheating before combustion.

Characteristics of HFO:

- High energy content (38-42 MJ/kg) provides cost-effective heat generation.

- Requires preheating to 100-150°C for proper atomization.

- High sulfur and ash content require advanced emission control systems.

| HFO Advantages | HFO Disadvantages |

|---|---|

| Lower cost per unit of energy | Requires fuel preheating |

| Suitable for large industrial applications | Produces more emissions |

| High calorific value | Requires advanced flue gas cleaning |

HFO is mainly used in power plants, cement manufacturing, and large-scale industrial heating.

4. Marine Fuel Oils (MFOs)

Marine fuel oils, including Marine Diesel Oil (MDO) and Intermediate Fuel Oil (IFO), are used in shipping and large industrial plants.

Marine Fuel Oil Categories:

- MDO (Marine Diesel Oil): A distillate fuel similar to LFO but optimized for marine engines and industrial turbines.

- IFO (Intermediate Fuel Oil): A blend of HFO and distillate fuels, requiring preheating.

| MFO Type | Viscosity (cSt at 50°C) | Application |

|---|---|---|

| MDO | 5-11 | Ships, turbines, industrial backup power |

| IFO 180 | ~180 | Large marine engines, industrial boilers |

| IFO 380 | ~380 | Large power plants, heavy industries |

MFOs are often used in locations where strict emission regulations are not enforced.

5. Biodiesel and Renewable Fuel Oils

Biodiesel and synthetic fuel oils are emerging alternatives for reducing carbon emissions.

Biodiesel Features:

- Derived from vegetable oils, animal fats, or waste oils.

- Lower sulfur content (less than 0.01%), reducing SO₂ emissions.

- Can be blended with LFO or used as a standalone fuel.

| Biodiesel Advantages | Biodiesel Disadvantages |

|---|---|

| Renewable and biodegradable | Slightly lower energy content |

| Reduces greenhouse gas emissions | Higher cost compared to fossil fuels |

| Compatible with existing boiler systems | May require storage modifications |

Biodiesel is commonly used in environmentally conscious industries, including food processing and municipal heating.

6. Key Considerations for Selecting Fuel Oil

When choosing the right fuel oil for an industrial boiler, several factors must be evaluated:

| Factor | Impact on Boiler Operation |

|---|---|

| Energy Content | Affects combustion efficiency and heat output |

| Viscosity | Determines fuel handling and preheating needs |

| Sulfur Content | Influences emissions and regulatory compliance |

| Cost & Availability | Affects overall operational expenses |

High-sulfur fuel oils require flue gas desulfurization systems, while low-viscosity fuels improve burner efficiency.

How Do Modern Industrial Oil-Fired Boilers Improve Efficiency and Reduce Emissions?

Industrial oil-fired boilers play a critical role in power generation, manufacturing, and heating applications. However, concerns over fuel costs and environmental impact have driven the development of advanced technologies to improve efficiency and reduce emissions. Modern industrial oil-fired boilers incorporate high-efficiency combustion systems, heat recovery technologies, and advanced emission controls to meet stringent environmental regulations while maximizing fuel utilization.

Modern industrial oil-fired boilers achieve higher efficiency and lower emissions through advanced burner designs, flue gas recirculation (FGR), economizers, and low-NOx combustion technologies. These features reduce fuel consumption, optimize heat transfer, and minimize pollutants such as nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter.

Adopting modern boiler technologies not only improves energy savings but also ensures compliance with environmental regulations, reducing operational costs and ecological impact.

High-efficiency oil-fired boilers can achieve over 95% thermal efficiency.True

Advanced heat recovery systems, improved burner technology, and optimized heat transfer contribute to efficiencies exceeding 95%.

1. High-Efficiency Burners for Optimized Combustion

One of the key advancements in modern industrial oil-fired boilers is the development of high-efficiency burners. These burners optimize fuel-air mixing, ensuring complete combustion and minimizing unburned hydrocarbons.

Key Features of Modern Burners:

- Low NOx Burners: Reduce nitrogen oxide emissions by optimizing combustion temperature and air distribution.

- Flame Stabilization Technology: Ensures efficient fuel combustion across different operating loads.

- Oxygen Trim Controls: Adjust the air-to-fuel ratio dynamically to maintain peak efficiency.

| Burner Technology | Efficiency Improvement (%) | Emission Reduction (%) |

|---|---|---|

| Conventional Burner | Baseline | Baseline |

| Low NOx Burner | +5% | -50% NOx |

| Oxygen Trim System | +3-5% | -10% CO₂ |

| Ultra-Low NOx Burner | +8-12% | -70% NOx |

Implementing these technologies helps reduce fuel consumption and maintain consistent boiler performance.

2. Heat Recovery Systems: Maximizing Energy Utilization

Modern oil-fired boilers use heat recovery devices to improve overall system efficiency. The most common heat recovery technologies include economizers and condensing heat exchangers.

Types of Heat Recovery Systems:

| Heat Recovery Technology | Function | Efficiency Gain (%) |

|---|---|---|

| Economizers | Capture waste heat from flue gases to preheat feedwater | +5-10% |

| Condensing Heat Exchangers | Recover latent heat from water vapor in exhaust gases | +10-15% |

| Air Preheaters (APHs) | Use flue gas heat to warm incoming combustion air | +3-8% |

Benefits of Heat Recovery Systems:

- Reduce fuel consumption by utilizing waste heat.

- Lower operating costs by improving thermal efficiency.

- Decrease carbon emissions by reducing excess energy loss.

3. Flue Gas Recirculation (FGR) for Low NOx Emissions

Flue Gas Recirculation (FGR) is a widely used technology to minimize nitrogen oxide (NOx) emissions. This system recirculates a portion of the flue gas back into the combustion chamber, reducing flame temperature and slowing NOx formation.

How FGR Works:

- A controlled amount of flue gas is redirected from the stack to the burner.

- The recirculated gas dilutes oxygen levels, lowering combustion temperatures.

- Lower temperatures reduce thermal NOx formation, cutting overall emissions.

| FGR Type | NOx Reduction (%) | Efficiency Impact |

|---|---|---|

| Conventional FGR | 20-40% | Slightly Reduced |

| Advanced FGR | 50-80% | Minimal Efficiency Loss |

By integrating FGR with low-NOx burners, industrial boilers can achieve significant reductions in emissions without sacrificing efficiency.

4. Advanced Control and Automation Systems

Modern industrial oil-fired boilers feature intelligent control systems that enhance efficiency and reduce emissions through real-time monitoring and adjustments.

Key Control Features:

- Combustion Optimization Software: Adjusts fuel and air ratios for maximum efficiency.

- Load Tracking Sensors: Adjust heat output based on demand fluctuations.

- Emission Monitoring Systems: Ensure compliance with environmental standards.

| Automation Feature | Efficiency Improvement (%) | Emission Reduction (%) |

|---|---|---|

| Oxygen Trim Control | +2-5% | -5-10% CO₂ |

| Real-Time Monitoring | +3-7% | -10-20% NOx |

| Adaptive Fuel Control | +4-6% | -15% Particulate Matter |

These smart systems minimize energy waste and enhance boiler longevity.

5. Fuel Quality and Low-Sulfur Oil Selection

The type of fuel used in industrial oil-fired boilers significantly impacts efficiency and emissions. High-quality, low-sulfur fuel oils reduce SOx emissions and improve combustion efficiency.

Fuel Quality Considerations:

- Low-Sulfur Fuel Oils (LSFO): Reduce sulfur dioxide (SO₂) emissions.

- Biodiesel Blends: Offer renewable, cleaner-burning alternatives.

- High-Grade Distillates: Ensure more complete combustion with fewer residues.

| Fuel Type | Sulfur Content (%) | Emission Impact |

|---|---|---|

| Heavy Fuel Oil (HFO) | 1.0-3.5 | High SOx Emissions |

| Low-Sulfur Fuel Oil (LSFO) | <0.5 | Reduced SOx |

| Ultra-Low Sulfur Diesel (ULSD) | <0.0015 | Near-Zero SOx |

| Biodiesel (B20-B100) | 0 | Carbon-Neutral Option |

Switching to cleaner fuel options is one of the most effective ways to meet emissions regulations.

6. Advanced Emission Control Technologies

Modern industrial oil-fired boilers use multiple emission control technologies to meet stringent environmental standards.

Key Emission Control Systems:

- Selective Catalytic Reduction (SCR): Uses ammonia or urea injection to reduce NOx by up to 90%.

- Electrostatic Precipitators (ESP): Capture fine particulate matter from flue gases.

- Flue Gas Desulfurization (FGD): Removes sulfur oxides (SOx) through chemical reactions.

| Technology | Pollutant Targeted | Reduction Efficiency (%) |

|---|---|---|

| SCR System | NOx | 70-90% |

| ESP | Particulate Matter | 95-99% |

| FGD | SO₂ | 85-98% |

By integrating these systems, modern boilers can achieve near-zero emissions.

What Are the Key Maintenance Practices for an Industrial Oil-Fired Boiler?

Industrial oil-fired boilers play a vital role in manufacturing, power generation, and heating applications. However, to ensure efficient operation, reduce fuel costs, and extend service life, routine maintenance is essential. Poor maintenance can lead to reduced efficiency, higher emissions, costly repairs, and even hazardous conditions. Regular servicing helps prevent breakdowns, improve fuel combustion, and ensure compliance with environmental regulations.

Key maintenance practices for industrial oil-fired boilers include regular inspections, burner maintenance, fuel system checks, cleaning of heat exchangers, monitoring water chemistry, and ensuring proper safety controls. Routine maintenance enhances boiler efficiency, reduces emissions, prevents unplanned downtime, and prolongs the equipment’s lifespan.

A well-maintained boiler not only operates at peak performance but also ensures workplace safety and regulatory compliance. Industries relying on oil-fired boilers should implement a structured maintenance schedule to avoid operational disruptions and costly repairs.

Neglecting oil-fired boiler maintenance can lead to a 10-20% decrease in efficiency.True

Carbon deposits, soot buildup, and burner misalignment reduce heat transfer and increase fuel consumption.

1. Daily Boiler Maintenance Checklist

To ensure smooth operation, operators should perform daily checks on critical components. These routine inspections help detect potential issues before they escalate.

Daily Maintenance Tasks:

- Check fuel levels to ensure an adequate supply.

- Inspect burner operation for stable flame and proper ignition.

- Monitor boiler pressure and temperature to detect abnormal fluctuations.

- Check for leaks in fuel lines, water piping, and steam connections.

- Observe flue gas emissions to identify combustion inefficiencies.

| Daily Maintenance Task | Why It’s Important |

|---|---|

| Check burner flame | Ensures complete combustion and prevents fuel wastage |

| Monitor pressure & temperature | Prevents unsafe operating conditions |

| Inspect fuel lines | Prevents leaks and fire hazards |

| Observe emissions | Identifies inefficient combustion |

Consistent daily checks minimize operational risks and fuel wastage.

2. Weekly and Monthly Maintenance Practices

Beyond daily checks, weekly and monthly maintenance includes deeper inspections and minor servicing to maintain boiler efficiency.

Weekly Maintenance Tasks:

- Clean burner nozzles and electrodes to prevent fuel deposits.

- Check combustion air supply for blockages or restrictions.

- Inspect oil filters and replace if clogged.

- Test flame safeguard system to ensure proper ignition and safety.

Monthly Maintenance Tasks:

- Inspect heat exchanger surfaces for soot or scale buildup.

- Test water level controls to prevent dry firing.

- Lubricate moving parts like fuel pumps and motor bearings.

- Check electrical connections to avoid faulty wiring.

| Task | Frequency | Purpose |

|---|---|---|

| Clean burner nozzles | Weekly | Ensures efficient fuel spray |

| Inspect oil filters | Weekly | Prevents clogging and fuel starvation |

| Check heat exchanger | Monthly | Improves heat transfer efficiency |

| Lubricate fuel pumps | Monthly | Prevents wear and tear |

Regular maintenance ensures optimal combustion and system longevity.

3. Quarterly and Annual Boiler Inspections

Quarterly Maintenance Tasks:

- Inspect and test boiler safety valves for proper operation.

- Perform combustion efficiency testing to adjust air-fuel ratios.

- Clean and inspect the flue gas stack for soot and corrosion.

- Test boiler controls and alarms for safety compliance.

Annual Maintenance Tasks:

- Conduct a thorough internal inspection for wear and corrosion.

- Descale and clean heat exchangers to remove hard deposits.

- Inspect fuel tanks for contamination like water or sludge buildup.

- Calibrate pressure and temperature sensors to maintain accuracy.

| Task | Frequency | Importance |

|---|---|---|

| Safety valve testing | Quarterly | Prevents overpressure hazards |

| Flue gas inspection | Quarterly | Reduces emission risks |

| Heat exchanger cleaning | Annually | Improves efficiency and lifespan |

| Sensor calibration | Annually | Ensures precise system control |

Annual maintenance ensures long-term reliability and compliance with safety regulations.

4. Cleaning and Preventative Maintenance

Cleaning Heat Exchangers and Boiler Tubes

- Soot and carbon deposits reduce heat transfer efficiency.

- Regularly clean tubes and surfaces with brushes or chemical treatments.

- Inspect for corrosion and scaling.

Preventing Fuel System Issues

- Check oil storage tanks for water contamination.

- Replace oil filters and fuel nozzles to prevent clogging.

- Inspect pumps and piping for leaks or pressure drops.

Boiler Water Treatment

- Monitor pH levels to prevent corrosion and scale formation.

- Use water softeners to reduce mineral deposits.

- Conduct blowdown procedures to remove impurities.

| Preventative Maintenance Task | Why It’s Important |

|---|---|

| Clean heat exchangers | Ensures efficient heat transfer |

| Monitor fuel system | Prevents burner malfunctions |

| Treat boiler water | Reduces scaling and corrosion |

Preventative maintenance maximizes performance and minimizes repair costs.

5. Advanced Boiler Monitoring and Automation

Modern industrial oil-fired boilers incorporate automated monitoring systems to improve efficiency and detect early signs of failure.

Key Automation Features:

- Remote monitoring for real-time performance tracking.

- Automatic fuel-air ratio control to optimize combustion.

- Predictive maintenance analytics to prevent unexpected failures.

- Emission monitoring to ensure regulatory compliance.

| Automation Feature | Benefit |

|---|---|

| Real-time monitoring | Detects performance issues early |

| Automated combustion control | Improves fuel efficiency |

| Emission tracking | Ensures environmental compliance |

Automation reduces maintenance workload and improves reliability.

6. Common Boiler Maintenance Issues and Troubleshooting

Even with proper maintenance, occasional issues may arise. Here are common boiler problems and solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Soot buildup on heat exchanger | Poor combustion or excess fuel | Clean exchanger and adjust burner settings |

| Unstable burner flame | Blocked fuel nozzle or air imbalance | Clean nozzle and check air-fuel ratio |

| High fuel consumption | Inefficient combustion or dirty components | Perform combustion tuning and clean system |

| Low steam pressure | Scaling in heat exchanger or water issues | Descale and check water levels |

Proper troubleshooting ensures reliable performance and avoids costly shutdowns.

What Industries Benefit the Most from Using Industrial Oil-Fired Boilers?

Industrial oil-fired boilers play a crucial role in a wide range of industries, providing reliable and efficient heat generation for various processes. These boilers are particularly beneficial in industries where stable, high-temperature heat is required, and alternative fuel sources such as natural gas or biomass may not be feasible. Oil-fired boilers offer advantages such as rapid startup, high thermal efficiency, and adaptability to different operational requirements.

Industries that benefit the most from industrial oil-fired boilers include manufacturing, power generation, chemical processing, food and beverage, hospitals, marine and shipping, textiles, oil refineries, and district heating. These sectors rely on oil-fired boilers for consistent steam and heat supply, ensuring uninterrupted production, energy efficiency, and compliance with environmental standards.

Many industries choose oil-fired boilers due to their flexibility in fuel selection, ease of installation, and ability to function in areas with limited access to natural gas. These advantages make them a valuable asset in both industrial and commercial applications.

Industrial oil-fired boilers can achieve efficiencies of up to 90% with proper maintenance.True

Advanced burner technology and heat recovery systems allow oil-fired boilers to maximize fuel utilization and minimize heat loss.

1. Manufacturing and Heavy Industry

Industrial oil-fired boilers are widely used in manufacturing and heavy industries due to their ability to provide continuous high-pressure steam and process heat.

Key Applications in Manufacturing:

- Metal processing – Heat treatment, forging, and metal casting require high-temperature steam.

- Automotive production – Used in painting booths, metal fabrication, and curing processes.

- Electronics industry – Precise temperature control for soldering, component manufacturing, and assembly.

| Manufacturing Process | Boiler Function |

|---|---|

| Metal casting and forging | Provides high-temperature heat for melting and shaping metals |

| Automotive painting | Maintains controlled heating for drying and curing |

| Semiconductor fabrication | Supplies steam for component cleaning and processing |

Industrial oil-fired boilers support high-temperature industrial applications, improving efficiency and product quality.

2. Power Generation and Utilities

Power plants and utilities use oil-fired boilers for backup energy production, cogeneration, and peak load balancing.

Benefits in Power Generation:

- Reliable backup power – Ensures electricity supply in remote areas.

- Co-generation (CHP) – Generates both electricity and heat for industrial applications.

- Quick startup and load adjustment – Ideal for peak demand periods.

| Application | Advantage of Oil-Fired Boilers |

|---|---|

| Backup power plants | Provides instant energy generation during grid failures |

| Combined heat and power (CHP) | Maximizes fuel efficiency by generating both power and process heat |

| Remote energy generation | Functions in areas with no natural gas infrastructure |

Power plants rely on oil-fired boilers to supplement energy production when renewable or gas-fired sources are unavailable.

3. Chemical and Petrochemical Industries

The chemical industry requires precise temperature control for distillation, chemical reactions, and material processing. Oil-fired boilers are preferred for their stability and adaptability.

Common Chemical Industry Applications:

- Distillation and refining – Fractional distillation of chemicals and petroleum products.

- Chemical synthesis – Provides steam for mixing and reaction control.

- Solvent recovery – Used in recycling and purification processes.

| Chemical Process | Importance of Oil-Fired Boilers |

|---|---|

| Fractional distillation | Provides consistent heat for separation of chemical compounds |

| Polymerization | Maintains stable temperatures for plastics and synthetic materials |

| Solvent recovery | Aids in purification and waste heat recovery |

Chemical plants require precise heat control, making oil-fired boilers an efficient and dependable solution.

4. Food and Beverage Processing

The food industry depends on oil-fired boilers for steam generation in cooking, sterilization, and packaging.

Food Industry Applications:

- Dairy processing – Pasteurization and sterilization of milk products.

- Beverage production – Brewing, distillation, and fermentation.

- Baking and confectionery – Provides controlled heating for ovens and drying.

| Food Process | Boiler Function |

|---|---|

| Pasteurization | Heats milk and juices to eliminate bacteria |

| Brewing and distillation | Supplies steam for beer, spirits, and wine production |

| Baking and drying | Maintains consistent temperatures for food processing |

Hygiene and temperature control are critical in food production, making oil-fired boilers essential for food safety and quality.

5. Healthcare and Hospitals

Hospitals and healthcare facilities require a constant supply of hot water and steam for sterilization, heating, and laundry services.

Hospital Boiler Applications:

- Sterilization of medical equipment

- Heating hospital buildings

- Laundry and sanitation

| Hospital Requirement | Oil-Fired Boiler Function |

|---|---|

| Equipment sterilization | Provides high-temperature steam for disinfection |

| Space heating | Supplies hot water and heating for patient comfort |

| Laundry services | Ensures hygienic washing of linens and uniforms |

Reliable boiler operation ensures critical medical services remain uninterrupted.

6. Marine and Shipping Industry

Oil-fired boilers are widely used in the marine sector for ship propulsion, heating, and auxiliary power generation.

Marine Boiler Uses:

- Propulsion for steam-driven ships

- Heating systems for cargo and crew accommodations

- Steam turbines for power generation

| Marine Application | Boiler Role |

|---|---|

| Cargo heating | Maintains correct temperatures for oil and gas transport |

| Engine room heating | Provides auxiliary heat for ship operations |

| Power generation | Supplies steam for electrical systems onboard |

The shipping industry relies on oil-fired boilers to power vessels efficiently across long distances.

7. Textile Industry

Oil-fired boilers play a key role in the textile manufacturing process, providing steam for dyeing, finishing, and pressing.

Textile Industry Applications:

- Dyeing and printing – Steam is essential for color

What Is an Industrial Oil-Fired Boiler and How Does It Work? Read More »