Environmental and Emission Regulations Impacting Industrial Coal-Fired Boiler Selection

Environmental and Emission Regulations Impacting Industrial Coal-Fired Boiler Selection

Coal-fired boilers remain a critical heat and power source in many industrial sectors—but they are also among the most heavily regulated due to their potential to emit high levels of pollutants, including particulate matter (PM), sulfur oxides (SOx), nitrogen oxides (NOx), and carbon dioxide (CO₂). Ignoring or underestimating these regulatory pressures during the boiler selection process can lead to permit denials, non-compliance penalties, expensive retrofits, or forced shutdowns. That’s why understanding environmental and emission standards is essential when choosing a coal-fired boiler for your operation.

Environmental and emission regulations impact industrial coal-fired boiler selection by dictating allowable pollutant output levels and requiring specific emissions control technologies. These include air quality standards for SOx, NOx, PM, CO, and CO₂ under frameworks such as the U.S. EPA’s Clean Air Act, the EU Industrial Emissions Directive (IED), and national/local regulatory agencies. Compliance influences key decisions such as boiler design, fuel quality, combustion control systems, flue gas desulfurization, and ash handling systems.

Here’s a structured look at how these regulations affect your decision-making process.

What Pollutants Are Regulated for Industrial Coal-Fired Boilers and Why Do They Matter?

Coal remains a widely used fuel in industrial boilers for steam and heat generation due to its affordability and availability. However, burning coal releases a complex mix of pollutants that have significant environmental and health impacts. To mitigate these risks, environmental authorities around the world enforce strict emissions regulations on coal-fired boiler systems. These rules are not only about legal compliance—they’re about protecting public health, ensuring workplace safety, and reducing long-term ecological damage. Failure to comply with these pollutant limits can lead to severe penalties, reputational damage, or even shutdown orders.

The main pollutants regulated in industrial coal-fired boilers include particulate matter (PM), sulfur dioxide (SO₂), nitrogen oxides (NOₓ), carbon monoxide (CO), carbon dioxide (CO₂), heavy metals like mercury (Hg), and volatile organic compounds (VOCs). These substances are harmful because they contribute to air pollution, smog, acid rain, respiratory diseases, and global warming. Regulatory compliance requires careful emission monitoring, fuel quality control, and the use of effective pollution control technologies.

Whether you’re running a small process boiler or a large utility plant, understanding what pollutants are regulated and why they matter is essential for both operational success and environmental responsibility.

Coal-fired boilers emit regulated pollutants such as particulate matter, sulfur oxides, and nitrogen oxides.True

Combustion of coal releases multiple harmful pollutants, and environmental regulations are designed to control their concentration in emissions.

🧪 Key Regulated Pollutants from Coal-Fired Boilers

| Pollutant | Source in Combustion Process | Why It Matters | Typical Limit (mg/Nm³) |

|---|---|---|---|

| Particulate Matter (PM10/PM2.5) | Ash, unburnt carbon, soot | Causes respiratory illness, haze | 30–50 (EU), 50–100 (India) |

| Sulfur Dioxide (SO₂) | Sulfur in coal reacts with O₂ | Acid rain, eye and lung irritation | 100–400 |

| Nitrogen Oxides (NOₓ) | High-temp oxidation of nitrogen in air/fuel | Smog, ozone, lung damage | 150–300 |

| Carbon Monoxide (CO) | Incomplete combustion | Toxic, reduces oxygen in bloodstream | 100–200 |

| Carbon Dioxide (CO₂) | Combustion of carbon | Major greenhouse gas | Not capped (reported under ETS) |

| Mercury (Hg) | Trace in coal vaporizes in flue gas | Neurotoxic, bioaccumulates in fish | <0.05 |

| VOCs/Dioxins | From incomplete combustion or fuel impurities | Carcinogenic, toxic, persistent | VOCs: 10–50 |

The exact limits vary by region, boiler capacity, and coal type, but all industrial users are responsible for managing these emissions.

🌍 Global Regulatory Frameworks for Coal Boiler Emissions

| Region | Regulatory Standard | Covered Pollutants |

|---|---|---|

| EU | Industrial Emissions Directive (2010/75/EU) | PM, SO₂, NOₓ, Hg, VOCs |

| USA | EPA MACT Rules, NSPS (40 CFR Part 60) | PM, SO₂, NOₓ, Hg, HCl, CO |

| India | CPCB Emission Norms (Revised 2017) | PM, SO₂, NOₓ, Hg |

| China | GB 13271-2014 | PM, NOₓ, SO₂ |

| Australia | NEPM and state-specific EPA regulations | PM, NOₓ, SO₂ |

Non-compliance can lead to:

Daily fines

Suspension of licenses

Public environmental penalties

Closure under Clean Air or Pollution Control Acts

🔬 How Each Pollutant Affects Environment and Health

| Pollutant | Human Health Impact | Environmental Effect |

|---|---|---|

| PM2.5 | Penetrates lungs and bloodstream | Reduces visibility, soil and water acidification |

| SO₂ | Asthma, bronchitis, eye irritation | Causes acid rain, damages crops |

| NOₓ | Triggers asthma, reduces lung function | Reacts with sunlight to form ozone |

| CO | Binds to hemoglobin, reduces oxygen delivery | Indoor air hazard, causes dizziness |

| Hg | Damages nervous system, especially in children | Enters water systems, bioaccumulates |

| CO₂ | No direct health effects | Main driver of global warming |

This is why governments enforce strict limits and require monitoring systems like CEMS (Continuous Emission Monitoring Systems) in larger operations.

🔧 Pollution Control Technologies Matched to Pollutants

| Pollutant | Control Technology | Effectiveness (%) |

|---|---|---|

| PM | ESP, Baghouse Filter | 99–99.9% |

| SO₂ | Wet scrubbers, Dry sorbent injection | 85–98% |

| NOₓ | SNCR, SCR, low-NOₓ burners | 50–95% |

| CO | Combustion tuning, air ratio adjustment | 60–90% |

| Hg/VOCs | Activated carbon injection (ACI) | 80–95% |

Proper technology selection depends on fuel characteristics, stack limits, and economic feasibility.

📊 Pollutant Contribution by Fuel Type

| Coal Grade | Ash (%) | Sulfur (%) | NOₓ Potential | PM Risk | SO₂ Emissions |

|---|---|---|---|---|---|

| Bituminous Coal | 10–15 | 0.5–1.5 | High | Medium | Moderate–High |

| Lignite | 15–30 | 0.3–1.0 | Moderate | High | High |

| Anthracite | <10 | <0.6 | Low–Moderate | Low | Low |

| Petroleum Coke | <5 | >2.5 | High | Low | Very High |

Knowing the fuel type and pollutant profile helps guide technology selection, fuel treatment, and monitoring strategy.

🧪 Case Study: Paper Mill Coal Boiler in Poland

Fuel: Bituminous coal

Emission Challenge: NOₓ > 300 mg/Nm³ and PM > 60 mg/Nm³

Actions Taken:

Installed SNCR for NOₓ

Upgraded to baghouse filter for PM

Optimized excess air control

Results:

NOₓ reduced to 180 mg/Nm³

PM reduced to 18 mg/Nm³

Passed IED stack test

Saved €140,000 annually in fuel and pollution tax

In conclusion, regulating and managing pollutants from coal-fired boilers is essential for both legal compliance and environmental stewardship. Particulate matter, sulfur oxides, nitrogen oxides, and heavy metals like mercury are tightly controlled due to their severe health and ecological impacts. Facilities that monitor emissions, choose appropriate fuels, and implement targeted control technologies can reduce pollution, avoid penalties, and operate more efficiently. In a carbon- and cost-conscious world, clean combustion isn’t just a regulatory obligation—it’s a business imperative.

Which International and Regional Regulations Apply to Coal-Fired Boiler Emissions?

Coal-fired industrial boilers are subject to some of the most rigorous environmental regulations in the world due to their significant contribution to air pollution and greenhouse gas emissions. These systems emit a wide range of pollutants—including particulate matter (PM), sulfur dioxide (SO₂), nitrogen oxides (NOₓ), carbon monoxide (CO), carbon dioxide (CO₂), and toxic heavy metals such as mercury (Hg). In response, countries and regional blocs have developed detailed emissions standards and compliance mechanisms that require continuous monitoring, pollution control technologies, and transparent reporting.

International and regional regulations governing coal-fired boiler emissions include the European Union’s Industrial Emissions Directive (IED), the United States Environmental Protection Agency’s MACT and NSPS standards, China’s GB13271-2014, India’s CPCB norms, and various state and provincial regulations in countries like Canada, Australia, and South Africa. These laws set legal limits for key pollutants such as PM, NOₓ, SO₂, Hg, and CO, and enforce compliance through permitting, emissions monitoring (CEMS), fines, and shutdown authority.

Operators must understand and comply with both national frameworks and regional-level mandates, which often differ in stringency and enforcement protocols depending on fuel type, boiler capacity, and facility location.

Coal-fired boiler emissions are regulated by both international guidelines and regional laws.True

Emission standards for coal boilers are enforced at multiple levels, including international protocols, regional agreements, and local legislation.

🌍 Major International and Regional Emissions Regulations

| Region/Country | Regulation Name/Body | Key Pollutants Covered | Enforcement Mechanism |

|---|---|---|---|

| European Union | Industrial Emissions Directive (2010/75/EU) | PM, NOₓ, SO₂, CO, VOCs, Hg, dioxins | Emission permits, BREF limits, CEMS |

| United States | EPA MACT (40 CFR Part 63), NSPS (Part 60) | PM, NOₓ, SO₂, CO, Hg, HCl | Stack testing, CEMS, penalties |

| China | GB13271-2014 | PM, SO₂, NOₓ, Hg | Real-time monitoring, fines, shutdown |

| India | CPCB Emission Norms (2017) | PM, NOₓ, SO₂, Hg | Mandated retrofits, inspection audits |

| Canada | Provincial Regulations + CCME Guidelines | PM, NOₓ, SO₂ | Provincial permits, GHG reporting |

| Australia | NEPM + State EPA Acts | PM, NOₓ, SO₂, CO | Region-specific caps and audits |

| South Africa | Air Quality Act 2004, Schedule 2 | PM, NOₓ, SO₂ | Emission licensing, rolling standards |

These laws are increasingly aligned with global environmental commitments, including Paris Agreement goals, national clean air programs, and climate disclosure frameworks.

📏 Typical Emission Limits by Region (for Coal Boilers >10 MWth)

| Pollutant | EU IED (mg/Nm³) | US EPA NSPS (mg/Nm³) | China GB13271 (mg/Nm³) | India CPCB (mg/Nm³) |

|---|---|---|---|---|

| PM | 10–30 | 30–50 | 30–50 | 50 |

| NOₓ | 150–200 | 200–300 | 200–300 | 300–400 |

| SO₂ | 100–200 | 150–300 | 200–400 | 100–600 |

| CO | 100–150 | 180–200 | 200–300 | 150–200 |

| Hg | <0.03 mg/Nm³ | <0.01 mg/Nm³ | <0.05 mg/Nm³ | <0.03 mg/Nm³ |

Note: Actual limits may vary by boiler size, age, and local authority discretion.

🛠️ How Regulations Influence Plant Design and Upgrades

| Regulatory Requirement | Engineering/Operational Response |

|---|---|

| PM < 30 mg/Nm³ | Add baghouse or high-efficiency ESP |

| NOₓ < 200 mg/Nm³ | Install SNCR/SCR or adopt low-NOₓ burners |

| SO₂ < 200 mg/Nm³ | Deploy FGD scrubbers or DSI systems |

| CEMS Mandatory | Implement certified continuous monitoring system |

| Hg reporting and capture | Use activated carbon injection or sorbents |

| CO₂ disclosure | Implement carbon accounting + ETS readiness |

Boiler manufacturers now pre-design units for regional compliance and often customize control systems based on applicable regulations.

🧪 Compliance Strategy Case Study – EU Industrial Boiler Retrofit

Location: Germany

Boiler Capacity: 30 MWth

Fuel: Bituminous coal

Challenge: Existing system exceeded new IED 2021 BREF limits

Actions Taken:

Installed high-efficiency ESP

Added SNCR system

Replaced old control panel with PLC-linked DAS

Outcomes:

PM reduced from 55 to 18 mg/Nm³

NOₓ dropped to 145 mg/Nm³

Compliant under BREF 2022

Annual CO₂ savings: 1,200 tons

ETS readiness confirmed

🧾 Reporting, Monitoring, and Enforcement Protocols

| Requirement | Jurisdiction Example | Description |

|---|---|---|

| CEMS Mandate | EU, China, India (>10 MW) | Real-time data to regulators |

| Annual Stack Testing | US, EU, Canada | Third-party audit of emissions |

| Emission Permit | All regions | Required before installation or retrofit |

| Fuel Use Reporting | US, EU | Tracks sulfur, ash, CV for modeling |

| ETS/Carbon Tax Submission | EU, Canada, SA | GHG tracking, subject to trading or taxation |

Non-compliance can trigger:

Regulatory fines (e.g., up to €100,000 in EU)

Legal injunctions

Public listing as a “polluting site”

Revocation of operating licenses

In conclusion, coal-fired boiler emissions are governed by a robust framework of international and regional environmental regulations. These rules exist to control pollutants that harm air quality, human health, and the climate. For industrial operators, compliance isn’t just about avoiding fines—it’s about designing, maintaining, and operating their boiler systems with emissions performance in mind. Understanding these regulations is the first step toward smarter investment, cleaner operations, and long-term sustainability.

How Do SOx, NOx, and PM Limits Affect Boiler Design and Fuel Selection?

In today’s regulatory environment, designing a coal-fired boiler system isn’t just a matter of thermal output or fuel cost—it’s a matter of emissions compliance. Specifically, the limits placed on sulfur oxides (SOₓ), nitrogen oxides (NOₓ), and particulate matter (PM) dictate many critical aspects of boiler design, combustion system configuration, and even which fuels are viable. These pollutants are among the most harmful to human health and the environment, and therefore, are tightly controlled by regulatory authorities worldwide. To comply, engineers must make careful, strategic decisions—because exceeding even one emission threshold can mean fines, shutdowns, or forced redesigns.

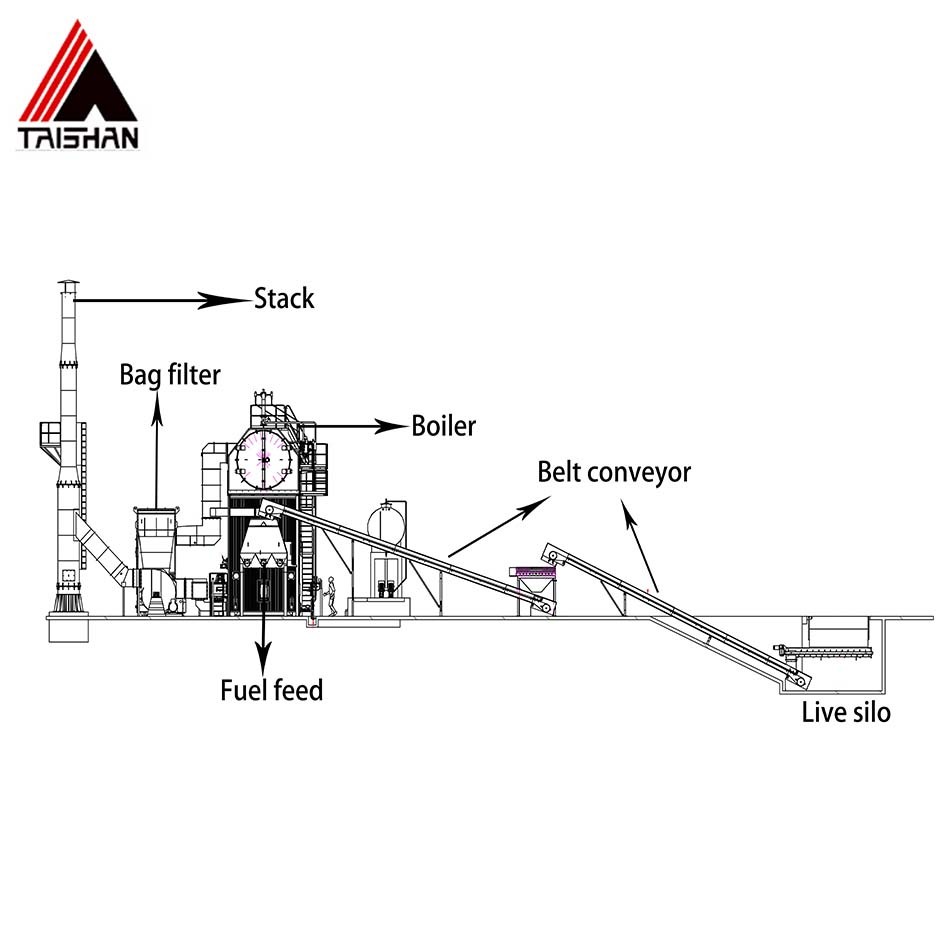

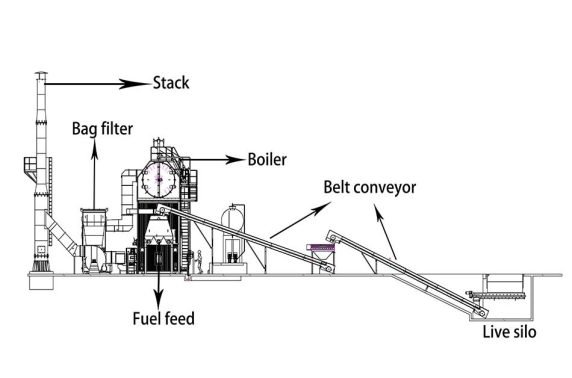

SOₓ, NOₓ, and PM emission limits significantly influence both boiler design and fuel selection. High SOₓ limits require flue gas desulfurization systems or the use of low-sulfur coal; strict NOₓ limits necessitate low-NOₓ burners, staged combustion, or SCR/SNCR systems; and tight PM limits demand advanced filtration such as baghouse filters or ESPs. These limits also affect the choice of coal type, pushing operators toward lower-ash, lower-sulfur fuels that are easier to control. As a result, compliance-driven design decisions directly impact capital costs, fuel procurement strategy, and operational efficiency.

Modern coal-fired systems are no longer designed just for heat—they are engineered for precision emissions performance. Understanding how each pollutant’s regulation shapes system requirements is critical for sustainable and legal boiler operation.

Strict SOx, NOx, and PM limits influence both the design of industrial boilers and the type of fuel that can be used.True

Tight emissions limits require design adjustments in combustion systems and influence fuel selection to reduce inherent pollutant formation.

🌍 Regulatory Landscape Driving Design Choices

| Pollutant | Common Regulatory Limit (mg/Nm³) | Typical Enforcement Regions |

|---|---|---|

| SO₂ | 100–400 | EU, China, India, US |

| NOₓ | 150–300 | EU, US, India, Australia |

| PM | 10–50 | EU, China, US, India |

These limits vary by boiler size, output (MWth), and local laws but universally drive technology selection and fuel procurement decisions.

🔧 Boiler Design Changes Triggered by SOₓ, NOₓ, and PM Limits

| Pollutant | Key Design Modifications | Purpose |

|---|---|---|

| SOₓ | – Wet/dry FGD systems- Limestone injection | Neutralize sulfur in flue gas |

| NOₓ | – Low-NOₓ burners- Flue Gas Recirculation (FGR)- SNCR/SCR systems | Reduce flame temperature or chemically reduce NOₓ |

| PM | – ESP (Electrostatic Precipitator)- Baghouse Filters- Multicyclones | Capture ash and soot before flue exit |

These systems are often integrated at the design phase for new builds or retrofitted to existing boilers based on updated regulations.

🌿 How Fuel Properties Affect Pollutant Emissions

| Fuel Type | Sulfur (%) | Ash (%) | Nitrogen (%) | SOₓ Risk | NOₓ Risk | PM Risk |

|---|---|---|---|---|---|---|

| Bituminous Coal | 0.5–1.5 | 10–15 | 0.8–1.5 | Moderate | High | Moderate |

| Anthracite | <0.5 | <10 | <1.0 | Low | Moderate | Low |

| Lignite | 0.6–1.5 | 15–30 | 1.0–2.0 | High | High | High |

| Petroleum Coke | >2.5 | <5 | <1.0 | Very High | High | Low |

Choosing a high-sulfur or high-ash fuel may be economically attractive, but will require expensive post-combustion controls to stay within legal limits.

🧰 Emissions Control Technology Matrix (Design Level)

| Pollutant | Best Control Technologies | Efficiency (%) | Impact on Design |

|---|---|---|---|

| SO₂ | – Wet Flue Gas Desulfurization (FGD)- Dry Sorbent Injection (DSI) | 85–98% | Adds absorber towers, ductwork |

| NOₓ | – Selective Non-Catalytic Reduction (SNCR)- Selective Catalytic Reduction (SCR) | 40–95% | Needs urea/ammonia system, catalyst beds |

| PM | – Bag Filters- Electrostatic Precipitators (ESP) | 99–99.9% | Requires large housing and fly ash handling |

These systems significantly impact boiler footprint, auxiliary power load, and O&M complexity.

📊 Design Impact Scenario: 20 MW Coal Boiler – Different Emission Standards

| Design Scenario | SO₂ Control | NOₓ Control | PM Control | Estimated CAPEX Impact |

|---|---|---|---|---|

| India CPCB 2017 | DSI | SNCR | Multicyclone | +25–30% over base |

| EU IED (BREF 2022) | Wet FGD | SCR | Baghouse | +45–60% over base |

| Legacy 1990s Boiler | None | Basic air control | Cyclone only | Not compliant |

Designing for stringent EU or EPA standards requires a multi-layered emissions control strategy, which can nearly double boiler capital cost—but ensures long-term compliance and efficiency.

🧪 Case Study: Retrofitting a Coal Plant to Meet New Emission Limits

Location: Northern China

Boiler: 35 TPH coal-fired system using local lignite

Initial State:

SO₂ emissions = 800 mg/Nm³

NOₓ = 420 mg/Nm³

PM = 120 mg/Nm³

All values exceeded GB13271-2014

Actions Taken:

Installed DSI + SNCR + baghouse filter

Switched to lower-sulfur Indonesian coal blend

Optimized combustion airflow

Post-Retrofit Results:

SO₂ reduced to 120 mg/Nm³

NOₓ reduced to 165 mg/Nm³

PM reduced to 28 mg/Nm³

Plant received new emissions permit

ROI on retrofit: 2.4 years through carbon credit eligibility

In conclusion, SOₓ, NOₓ, and PM emission limits are among the most powerful design drivers in coal-fired boiler systems. They affect everything from fuel selection to combustion system geometry, auxiliary equipment, and emissions monitoring infrastructure. Engineers and operators must design around these constraints from the outset or face costly retrofits and regulatory risks. In today’s zero-tolerance emission landscape, staying ahead means building systems that meet—not just current—but future emissions standards.

What Emissions Control Technologies Are Required for Compliance (e.g., ESP, FGD, SCR)?

Coal-fired boilers are powerful but pollutant-intensive systems. They emit high levels of particulate matter (PM), sulfur oxides (SOₓ), nitrogen oxides (NOₓ), carbon monoxide (CO), volatile organic compounds (VOCs), and toxic metals such as mercury (Hg). To operate within legal boundaries, especially under strict global regulations like the EU IED, US EPA MACT, India’s CPCB, and China’s GB13271, these boilers must be equipped with advanced emissions control technologies. Without them, even well-designed boilers cannot meet modern compliance thresholds—risking fines, shutdowns, or revoked permits.

To comply with emissions regulations, coal-fired industrial boilers must implement targeted control technologies such as Electrostatic Precipitators (ESP) or Bag Filters for PM removal, Flue Gas Desulfurization (FGD) for SO₂ reduction, Selective Catalytic Reduction (SCR) or Selective Non-Catalytic Reduction (SNCR) for NOₓ control, and Activated Carbon Injection (ACI) for mercury and VOCs. These technologies are essential for reducing emissions below regulatory limits and achieving operational permits.

Designing or retrofitting a boiler for emissions compliance is not optional—it’s an engineering, regulatory, and environmental necessity.

ESP, FGD, and SCR are essential technologies to meet PM, SO₂, and NOₓ limits respectively in coal-fired boilers.True

Each of these control systems targets specific pollutants and is required under most modern emissions standards worldwide.

📋 Required Emissions Control Technologies by Pollutant

| Pollutant | Required Control Technology | Removal Efficiency (%) | Description |

|---|---|---|---|

| Particulate Matter (PM) | ESP or Baghouse Filter | 99–99.9% | Captures fly ash, unburnt carbon, soot |

| Sulfur Dioxide (SO₂) | FGD (Wet or Dry) | 90–98% | Scrubs sulfur from flue gas using lime/limestone |

| Nitrogen Oxides (NOₓ) | SNCR or SCR | 40–95% | Converts NOₓ into nitrogen using urea or ammonia |

| Mercury (Hg) | ACI (Activated Carbon Injection) | 80–95% | Binds Hg vapor before filter collection |

| Carbon Monoxide (CO) | Combustion Control + O₂ Trim | 60–90% | Improves burn efficiency, prevents incomplete combustion |

| VOCs/Dioxins | ACI or Thermal Oxidizer | >90% | Destroys organic pollutants or captures with carbon |

| HCl (if present) | Dry Sorbent Injection (DSI) | 60–80% | Neutralizes acid gases |

Each technology must be selected based on the boiler size, fuel type, emission limit, and regulatory jurisdiction.

🔧 Technology Deep Dive: Key Systems Explained

1. Electrostatic Precipitator (ESP)

Uses electrostatic fields to trap fine particles

Best for medium-large boilers with moderate fly ash

Typically required when PM limits are <50 mg/Nm³

2. Baghouse Filter

Fabric filters that trap even submicron particulates

Preferred for ultra-low PM standards (EU BREF <10 mg/Nm³)

Requires compressed air for cleaning and dust hoppers

3. Flue Gas Desulfurization (FGD)

Wet FGD: High efficiency (90–98%), uses limestone slurry

Dry FGD or DSI: Lower capex, suitable for mid-range SO₂ loads

Often required for fuels with >1% sulfur

4. Selective Catalytic Reduction (SCR)

Injects ammonia over catalyst beds to reduce NOₓ to N₂

High capex, high efficiency (90–95%)

Required under strict EU and US standards

5. Selective Non-Catalytic Reduction (SNCR)

Simpler system injecting urea at high-temp zones

Moderate efficiency (40–70%), lower cost

Suitable for retrofits or smaller boilers

6. Activated Carbon Injection (ACI)

Injects powdered carbon before PM control device

Captures mercury, dioxins, and VOCs

Required when using high-Hg fuels or waste co-firing

📊 Technology Selection Matrix by Compliance Level

| Compliance Tier | PM Control | SO₂ Control | NOₓ Control | Mercury/VOCs |

|---|---|---|---|---|

| India CPCB (Standard) | ESP + Cyclone | DSI | SNCR | Optional |

| EU IED (BREF) | Bag Filter | Wet FGD | SCR | ACI Required |

| China GB13271 | ESP | Wet/Dry FGD | SNCR or SCR | Mandatory (Hg) |

| US EPA MACT | ESP + Bag Filter | Wet FGD | SCR | ACI + CEMS |

The more stringent the emission target, the more integrated and advanced the control systems need to be.

🧪 Real-World Compliance Strategy: 50 TPH Coal Boiler Retrofit (India)

Initial Emissions:

PM: 135 mg/Nm³

SO₂: 780 mg/Nm³

NOₓ: 420 mg/Nm³

Hg: not tracked

Retrofit Scope:

ESP upgraded with extra field

Installed DSI for SO₂

Added SNCR with urea system

Introduced Hg capture via ACI

Post-Retrofit Emissions:

PM: 28 mg/Nm³

SO₂: 180 mg/Nm³

NOₓ: 170 mg/Nm³

Hg: 0.02 mg/Nm³

ROI Period: 2.1 years (due to carbon credits + fine avoidance)

Status: CPCB 2017 + ISO 14001 certified

⚙️ Other Mandatory Compliance Add-ons

| Component | Purpose |

|---|---|

| CEMS | Real-time emission reporting |

| Ammonia/Urea Storage | For SCR/SNCR systems |

| Fly Ash Handling System | Required for bag filters and ESPs |

| pH and slurry controls | Needed for wet scrubbers |

| Emission Management SCADA | Centralized control and alerts |

These systems are not optional—they are legally required in most jurisdictions to prove emissions are under control continuously.

In conclusion, ESP, FGD, and SCR are cornerstone technologies for meeting compliance in coal-fired boiler systems, with ACI, SNCR, and bag filters supporting specialized pollutant control. The right selection and integration of these systems is dictated by emission limits, fuel type, and boiler design. As emissions regulations tighten globally, these technologies are no longer add-ons—they are compliance-critical components of every industrial combustion system. For any plant looking to operate legally and sustainably, the time to invest in emissions control is not after a violation—it’s at the design stage.

How Do Carbon Emissions Targets and Climate Policies Influence Boiler System Choices?

As countries around the world commit to net-zero carbon emissions and decarbonization pathways, traditional boiler systems—especially those powered by coal and heavy oil—are under intense scrutiny. Regulatory frameworks, carbon taxes, emission trading schemes, and climate-driven funding conditions are forcing industries to rethink their thermal energy strategies. For any new boiler project—or retrofitting an existing one—carbon emissions targets now influence system design as much as efficiency or output requirements. Choosing the wrong system can lead to regulatory non-compliance, stranded assets, and financial penalties. Choosing the right one can unlock subsidies, avoid carbon pricing burdens, and align with global sustainability goals.

Carbon emissions targets and climate policies strongly influence boiler system choices by favoring low-carbon fuels, high-efficiency combustion technologies, and carbon capture readiness. These policies discourage the use of coal and heavy oil boilers, promote electrification and biomass alternatives, and enforce emissions caps through carbon taxes or trading systems. As a result, industries are selecting boiler systems that not only meet thermal demand but also minimize CO₂ emissions per unit of output to remain compliant and cost-effective in a decarbonizing economy.

Modern boiler investment is no longer just an engineering decision—it’s a climate strategy.

Boiler system choices are increasingly influenced by climate policies and carbon emissions targets.True

Climate commitments and carbon pricing mechanisms are pressuring industries to select low-carbon boiler technologies to remain compliant and cost-effective.

🌍 Climate Policy Drivers That Influence Boiler Decisions

| Climate Policy Mechanism | Impact on Boiler Choices |

|---|---|

| Carbon Pricing (Taxes/ETS) | Penalizes high-emission fuels like coal and oil |

| Net-Zero Commitments (by 2050) | Encourages electrification and green hydrogen integration |

| NDCs under Paris Agreement | Forces reductions in industrial CO₂ intensity |

| Green Procurement Standards | Excludes fossil-fired systems from public sector funding |

| Climate-Focused Loans/Grants | Prioritize biomass, waste heat, and high-efficiency systems |

| Corporate ESG Reporting | Pushes investors toward clean thermal infrastructure |

These policies are converting carbon intensity from an “externality” to a cost line item in project evaluations.

📊 Carbon Intensity of Common Boiler Fuels

| Fuel Type | CO₂ Emissions (kg/MWh thermal) | Regulatory Burden (Trend) | Policy Risk Level |

|---|---|---|---|

| Coal (bituminous) | 340–400 | High | ⚠️ Very High |

| Heavy Fuel Oil | 300–350 | High | ⚠️ High |

| Natural Gas | 200–250 | Moderate (with mitigation) | 🟡 Medium |

| Wood/Biomass | ~30–50* (considered neutral) | Low to Zero | 🟢 Low |

| Electric Boiler (renewable grid) | 0 (scope 2 dependent) | Zero with green supply | 🟢 Very Low |

| Hydrogen (green) | 0 | Zero | 🟢 Emerging |

Biomass is typically considered CO₂-neutral under most climate accounting systems due to biogenic carbon cycles.

🔧 Boiler System Design Choices Affected by Climate Policies

| System Type | Carbon Policy Impact | Typical Policy Outcome |

|---|---|---|

| Coal-Fired Boiler | High taxes, banned in new projects | Being phased out globally |

| Oil-Fired Boiler | Carbon taxed, high reporting burden | Replaced by gas or bio-oil |

| Gas Boiler (Condensing) | Moderate compliance with carbon offset options | Still allowed with limits, CCS under study |

| Biomass Boiler (Grate/FB) | Favored in tax credits and clean investment | Encouraged for district heating, industrial use |

| Electric Boiler | Allowed under renewable grids | Best ESG score, low capacity for large steam |

| Waste Heat Recovery Boiler | Encouraged as energy efficiency project | Tax exempt or grant-eligible |

| Hydrogen-Ready Boiler | Promoted as future-proof tech | Included in decarbonization roadmaps |

🧰 Engineering Features in Carbon-Conscious Boiler Design

| Design Element | Role in Carbon Reduction |

|---|---|

| Condensing Economizers | Increase efficiency, reduce fuel per output |

| O₂ Trim and Air Ratio Control | Reduce excess air and stack loss |

| Fuel Flexibility | Enables biomass, RDF, or green gas blending |

| Integrated CEMS + Carbon Reporting | Supports transparent climate compliance |

| Modular Design for CCS | Prepares system for future carbon capture |

These features are often prerequisites for accessing green finance or sustainable infrastructure funds.

🧪 Case Study: Multinational FMCG Plant Redesign (Net-Zero Target)

Old System: 30 TPH coal-fired boiler (India), 85% thermal efficiency

Climate Mandate: Corporate net-zero by 2040

Compliance Issues: CO₂ emissions >19,000 t/year

Actions Taken:

Replaced with 20 TPH biomass fluidized bed boiler

Added CEMS and digital energy management system

Emissions dropped by 91% (to ~1,800 t/year, mostly from transport)

Carbon credit eligibility opened under Indian PAT + I-REC schemes

Result:

OPEX savings via avoided carbon tax

Compliant with parent company’s Science-Based Targets initiative (SBTi)

In conclusion, carbon emissions targets and climate policies are now central to boiler system selection and investment decisions. They dictate allowable fuels, acceptable emission intensities, and long-term operational costs. Facilities aiming for cost-efficient and regulation-proof boiler systems must now prioritize low-carbon technologies, fuel flexibility, and emission transparency. Designing for carbon compliance is no longer a luxury—it’s a competitive and regulatory requirement in the race toward industrial decarbonization.

Why Is Emissions Monitoring and Reporting Essential for Long-Term Regulatory Compliance?

For industrial facilities operating combustion systems—especially coal, biomass, or heavy-oil-fired boilers—emissions compliance is not a one-time checklist, but a continuous obligation. Authorities no longer accept handwritten logs or once-a-year stack testing. Instead, they require real-time emissions tracking, data logging, and automated reporting—a shift driven by global climate policies, public transparency demands, and increasingly strict air quality standards. Without a robust emissions monitoring and reporting system in place, companies face growing legal, financial, and reputational risks. This is why emissions monitoring and reporting is now a central pillar of environmental compliance for any long-term boiler operation.

Emissions monitoring and reporting are essential for long-term regulatory compliance because they provide continuous, verifiable evidence that pollutant levels such as PM, NOx, SO₂, CO, and CO₂ remain within legal limits. Real-time monitoring through certified systems like CEMS ensures rapid detection of exceedances, supports automated reporting to regulatory authorities, and helps avoid fines, shutdowns, or permit loss. Long-term data records also support audits, permit renewals, ESG disclosure, and climate reporting obligations.

Without proper monitoring, even compliant plants can be penalized simply for lack of proof—a critical issue as regulations increasingly focus on traceability and data transparency.

Continuous emissions monitoring is a legal requirement for many industrial boilers worldwide.True

Environmental regulations in regions like the EU, US, China, and India mandate the use of Continuous Emissions Monitoring Systems (CEMS) for certain boiler capacities.

📋 Why Regulators Require Continuous Monitoring and Reporting

| Regulatory Objective | Monitoring Role |

|---|---|

| Enforce Emission Limits | Ensure pollutants like NOₓ, SO₂, PM stay within thresholds |

| Provide Audit Trail | Verifiable data log for inspections and permits |

| Enable Real-Time Response | Detect and correct pollution spikes immediately |

| Support Climate Reporting | Submit CO₂ emissions for ETS or carbon tax purposes |

| Public Transparency | Share emissions data with communities, NGOs |

In many jurisdictions, failing to report is treated as equivalent to exceeding limits, and can result in automatic penalties.

🧰 What Is Required for Emissions Monitoring Compliance?

| Component | Description | Required For |

|---|---|---|

| Continuous Emissions Monitoring System (CEMS) | Tracks real-time levels of PM, NOₓ, SO₂, CO, O₂, etc. | Boilers >10–25 MW (EU, India, China, US) |

| Data Acquisition System (DAS) | Stores, timestamps, and sends emissions data | Central to compliance |

| Calibration System | Validates sensor accuracy (QAL2/3 or EPA protocols) | Required by law |

| Remote Data Transfer Module | Sends data to government portals (e.g., CPCB, EPA) | Mandatory in many regions |

| Annual Stack Test Equipment | Third-party testing for certification | Required for permit renewal |

Without these components, no emissions reporting program can be considered compliant under modern laws.

🌍 Regional Monitoring and Reporting Mandates

| Region | Legal Requirement | Boiler Scope |

|---|---|---|

| EU | IED (2010/75/EU) + BREF QAL requirements | >20 MWth, waste co-firing |

| USA | 40 CFR Part 60/75 CEMS, MACT rules | >25 MMBtu/hr boilers |

| China | GB13271-2014 + HJ212-2017 data protocols | >10 TPH industrial boilers |

| India | CPCB CEMS Notification + Online Reporting | >10 TPH or 15 MWth boilers |

| South Africa | NEM:AQA + Atmospheric Emission Licenses | >50 MW combustion installations |

Failing to comply can result in:

Fines up to €100,000/day (EU)

Shutdown orders (China, India)

Permit revocation and loss of operating license (US)

Legal prosecution and public blacklisting

📊 What Data Is Collected by Monitoring Systems?

| Pollutant/Parameter | Why It’s Monitored |

|---|---|

| NOₓ | Indicates combustion temperature control |

| SO₂ | Reflects sulfur content of fuel |

| PM | Measures filter/burner performance |

| CO | Detects incomplete combustion |

| O₂ | Helps assess air-fuel ratio efficiency |

| CO₂ | Tracks GHG emissions for reporting |

| Flue Temp | Identifies heat loss and efficiency drop |

| Steam/Fuel Flow | Enables thermal efficiency calculation |

The data is used not only for compliance, but also to optimize performance, reduce fuel use, and improve safety.

🔧 Real-World Example: Food Industry Steam Boiler (India)

Boiler Capacity: 20 TPH, rice husk-fired

Problem: Frequent NOₓ exceedances not detected in time

Solution:

Installed CEMS with NOₓ/PM/SO₂ analyzers

Added DAS with CPCB-linked portal reporting

Enabled alerts at 80% of limit

Result:

NOₓ exceedances dropped by 90%

Avoided ₹1.2 million in penalties in 12 months

Got renewal of consent-to-operate without audit delay

📈 Benefits Beyond Compliance

| Benefit | Description |

|---|---|

| Fuel Savings | Better combustion control through O₂ optimization |

| Maintenance Planning | Detects burner/fan wear early |

| Carbon Credit Eligibility | Required baseline for CO₂ tracking |

| Investor ESG Alignment | Proves environmental responsibility |

| Operational Benchmarking | Compare across units and time periods |

In a carbon-constrained economy, emissions data is not just for regulators—it’s for stakeholders, financiers, and customers too.

In conclusion, emissions monitoring and reporting are essential for long-term regulatory compliance in today’s industrial landscape. They ensure pollutant limits are continuously met, support transparent governance, and protect facilities from legal and financial consequences. With environmental standards tightening globally, investing in CEMS and reporting infrastructure is no longer a defensive move—it’s a proactive step toward sustainability, resilience, and long-term operational success.

🔍 Conclusion

Environmental and emission regulations are key drivers in the selection and design of industrial coal-fired boilers. From fuel choice to flue gas treatment, every aspect of the boiler system must be tailored to comply with current—and anticipate future—regulations. By integrating emissions compliance into your procurement process, you’ll avoid penalties, reduce environmental impact, and future-proof your operation in an increasingly regulated industrial landscape.

📞 Contact Us

💡 Need help selecting a compliant coal-fired boiler system? Our engineers provide emissions consulting, system design, and turnkey solutions that meet the most stringent environmental standards.

🔹 Let us help you build an efficient, compliant, and sustainable coal-fired boiler system. 🏭⚖️✅

FAQ

What environmental regulations impact coal-fired boiler selection?

Industrial coal-fired boilers must comply with regulations like the U.S. EPA Clean Air Act, EU Industrial Emissions Directive (IED), and local air quality laws. These set limits on SO₂, NOx, CO₂, PM, and mercury emissions, directly influencing boiler design, fuel type, and emission control systems.

Why is SO₂ emission control important in coal-fired boilers?

Coal often contains sulfur, which forms sulfur dioxide (SO₂) during combustion. To comply with limits, many systems require flue gas desulfurization (FGD) equipment, such as wet scrubbers or dry sorbent injection systems.

How do NOx regulations affect burner and combustion design?

To reduce nitrogen oxide (NOx) emissions—which contribute to smog and acid rain—regulators require the use of low-NOx burners, staged combustion, or selective catalytic reduction (SCR) technologies in industrial coal boiler systems.

What role do particulate matter (PM) standards play in boiler selection?

Coal combustion generates fine particulates (PM2.5 and PM10), which are tightly regulated. Systems must include electrostatic precipitators (ESP), baghouse filters, or cyclones to capture and control particulate emissions.

How do carbon emissions regulations influence coal boiler viability?

Global and regional efforts to reduce greenhouse gas (GHG) emissions, including carbon dioxide (CO₂), are pushing industries toward cleaner technologies. While coal-fired boilers are still viable, they must now meet stricter efficiency and carbon intensity thresholds, or risk penalties and regulatory constraints.

References

EPA Clean Air Act Standards for Boilers – https://www.epa.gov

EU Industrial Emissions Directive (IED) – https://www.europa.eu

SO₂ Control Technologies in Boilers – https://www.researchgate.net

NOx Reduction Strategies in Combustion Systems – https://www.sciencedirect.com

Particulate Matter and ESP in Industrial Boilers – https://www.bioenergyconsult.com

Greenhouse Gas Emissions from Coal Boilers – https://www.iea.org

Mercury and Heavy Metals Regulation – https://www.mdpi.com

Best Available Techniques for Coal Combustion – https://www.energysavingtrust.org.uk

Boiler Emission Control Equipment Guide – https://www.automation.com

Regulatory Trends in Industrial Boilers – https://www.sciencedirect.com

Wade Zhang

Environmental and Emission Regulations Impacting Industrial Coal-Fired Boiler Selection Read More »

-scaled.jpg)