How to Optimize Industrial Oil-Fired Boiler Performance for Lower Operating Costs

Industrial oil-fired boilers are valued for their high energy density, stable performance, and quick heat delivery. However, without proper optimization, they can become fuel-intensive, emission-heavy, and costly to operate. Many facilities lose thousands annually due to inefficient combustion, poor maintenance, and underutilized heat recovery. To improve operational efficiency and profitability, it’s essential to take a systematic approach to performance optimization.

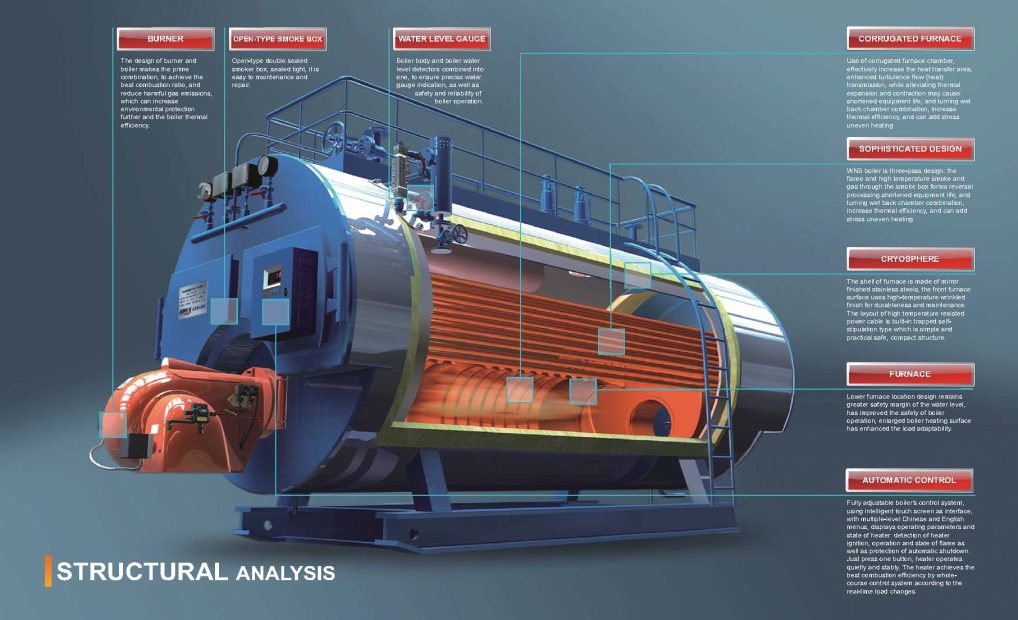

To optimize an industrial oil-fired boiler for lower operating costs, focus on improving combustion efficiency, maintaining clean heat transfer surfaces, minimizing excess air, utilizing flue gas heat recovery (e.g. economizers), and implementing predictive maintenance. Additional savings can be achieved by using high-quality fuel, adjusting load management strategies, and incorporating automation for real-time monitoring and control. Together, these measures reduce fuel consumption, lower emissions, and extend the boiler’s service life.

Here’s how to strategically improve the cost-efficiency of your oil-fired boiler system.

How Does Burner Tuning and Air-to-Fuel Ratio Adjustment Reduce Fuel Consumption?

Combustion is the heart of every biomass boiler—and just like any engine, its performance depends on precise tuning. A poorly adjusted burner wastes fuel by allowing too much air (excess oxygen) or too little (leading to incomplete combustion). Both conditions drive up fuel usage, increase emissions, and reduce efficiency. That’s why burner tuning and air-to-fuel ratio (AFR) control are essential tools for energy managers and plant engineers. Through proper tuning, consistent monitoring, and automated airflow control, facilities can reduce fuel consumption by 5%–15%, improve combustion stability, and lower maintenance costs.

Burner tuning and air-to-fuel ratio adjustment reduce fuel consumption by ensuring complete and efficient combustion. When the right amount of air is supplied relative to the fuel being burned, heat release is optimized, combustion losses are minimized, and emissions are reduced. Too much air cools the flame and carries heat out of the stack, while too little air causes unburned fuel and soot. Tuning adjusts the airflow, fuel feed, and burner performance to match load demand, fuel type, and oxygen levels. This balance lowers fuel use per unit of steam or heat produced.

If combustion is the engine, then tuning is your fuel-efficiency dial.

Air-to-fuel ratio tuning reduces fuel consumption by improving combustion efficiency and reducing stack heat losses.True

Correcting for excess air or insufficient oxygen ensures that more fuel energy is converted to usable heat.

🔥 What Is the Air-to-Fuel Ratio (AFR)?

The air-to-fuel ratio is the mass of air supplied per unit of fuel, typically expressed as:

Stoichiometric Ratio: Theoretical minimum air required for complete combustion

Excess Air: Air above stoichiometric, added to ensure full fuel burn

Biomass stoichiometric AFR (approx.):

Wood pellets: ~6:1

Wood chips (wet): ~8–9:1

Rice husk: ~7:1

Ideal excess air: 15–30% (actual ratio ~7–10:1 depending on fuel and moisture)

Too much air = heat wasted

Too little air = fuel wasted

📉 Effects of Improper AFR

| Condition | Consequence | Impact on Fuel Use |

|---|---|---|

| Too Much Air (Excess O₂) | Flame cooling, heat lost in flue gas | 5–10% fuel increase |

| Too Little Air | Incomplete combustion, CO, soot | 8–15% fuel loss |

| Unbalanced Distribution | Hot spots, corrosion, emissions | Burner wear, inefficiency |

Excess combustion air carries unburned heat up the stack, reducing thermal efficiency.True

Every 1% excess O₂ beyond optimal can reduce boiler efficiency by 0.5%–1%.

⚙️ Key Elements of Burner Tuning

| Tuning Parameter | What It Adjusts | Benefit |

|---|---|---|

| Primary/Secondary Air Flow | Controls oxygen available at burner | Optimizes flame temperature |

| Fuel Feed Rate | Matches combustion load demand | Prevents over- or underfeeding |

| O₂ Trim System | Adjusts airflow based on O₂ sensors | Maintains consistent efficiency |

| Flame Shape and Length | Balances combustion space utilization | Prevents tube overheating or sooting |

| Burner Turndown Ratio | Improves control at part load | Reduces cycling and losses |

Automated tuning with PLC/SCADA ensures 24/7 optimization and faster adjustment to load changes.

🧪 Case Study: 5 TPH Biomass Boiler with O₂ Tuning

| Before Tuning | After Tuning |

|---|---|

| Excess O₂: 6.8% | Optimized O₂: 3.5% |

| Fuel Use: 2,400 tons/year | Fuel Use: 2,160 tons/year |

| Efficiency: 73% | Efficiency: 79% |

| Annual Savings | 240 tons biomass (~$19,200) |

Payback on tuning system: <1 year

📋 Best Practices for Air-to-Fuel Optimization

| Practice | Result |

|---|---|

| Install O₂ sensors in flue stack | Enables real-time airflow adjustments |

| Calibrate airflow meters regularly | Ensures airflow matches readings |

| Check flame visuals during load change | Identifies imbalances visually |

| Automate burner management | Maintains AFR under all load conditions |

| Track O₂ vs. fuel ratio weekly | Diagnoses trends, prevents drift |

Monitoring tools like CEMS, PLC, or handheld flue gas analyzers are key to sustaining performance.

📈 AFR and Efficiency Relationship

| Excess O₂ (%) | Approx. Boiler Efficiency (%) |

|---|---|

| 2% | 85–87% |

| 4% | 83–84% |

| 6% | 80–82% |

| 8% | 77–79% |

| >10% | <75% |

Every 1% excess O₂ above optimal = ~0.5% to 1% efficiency loss

Summary

Burner tuning and air-to-fuel ratio adjustment are among the most effective and lowest-cost methods to reduce fuel consumption in biomass boiler systems. By minimizing excess air and optimizing combustion, operators can lower fuel use, increase thermal efficiency, reduce emissions, and extend component life. Whether done manually with regular checks or through automated O₂ trim systems, this process delivers fast, measurable ROI and is essential for long-term performance. For any fuel-fired system, efficient combustion starts with precise control—and ends with lower operating costs.

Why Is Cleaning Soot and Scale from Heat Exchanger Surfaces Essential for Thermal Efficiency?

In a biomass boiler system, the heat exchanger is where fuel energy becomes usable thermal energy. It transfers heat from hot combustion gases to water or steam. But over time, soot, ash, and mineral scale accumulate on these surfaces, forming insulating layers that choke off heat transfer. As these deposits grow, they reduce the boiler’s efficiency, increase fuel consumption, and raise flue gas temperatures. Without regular cleaning, these seemingly minor residues can cost thousands of dollars in wasted energy every year. Cleaning soot and scale is not just maintenance—it is a direct investment in efficiency and operating cost control.

Cleaning soot and scale from heat exchanger surfaces is essential for thermal efficiency because these deposits act as insulators that block effective heat transfer. Even thin layers of fouling reduce the rate at which combustion heat is transferred to water or steam, forcing the boiler to burn more fuel to produce the same output. Soot buildup from unburned biomass and mineral scale from water impurities can reduce efficiency by 5% to 15% or more. Regular cleaning restores optimal thermal conductivity, lowers stack temperatures, improves fuel economy, and prevents long-term damage to heat surfaces.

Neglecting fouling turns your heat exchanger into a fuel-wasting barrier.

Even thin layers of soot and scale significantly reduce heat transfer efficiency in boilers.True

Soot and scale are poor conductors of heat and form an insulating layer, requiring more fuel to achieve the same output.

🌫️ Impact of Fouling on Thermal Transfer

| Deposit Type | Source | Conductivity (W/m·K) | Heat Transfer Impact |

|---|---|---|---|

| Soot (carbon ash) | Incomplete combustion | ~0.1 | High insulating effect |

| Scale (calcium/silica) | Hard water minerals | ~0.2 – 0.4 | Moderate to severe |

| Clean steel surface | — | ~45 – 55 | Optimal performance |

Just 1 mm of soot or scale can reduce thermal conductivity by over 90%.

📉 How Fouling Affects Boiler Performance

| Fouling Level | Flue Gas Temp Rise | Efficiency Drop | Fuel Use Impact |

|---|---|---|---|

| Clean Tubes | Normal (~180°C) | 0% | Baseline |

| Light Fouling (0.5mm) | +20°C | -2–4% | +3–5% |

| Moderate (1mm) | +40°C | -6–8% | +7–10% |

| Severe (2mm+) | +80°C | -10–15% | +10–20% |

Fouled heat exchanger surfaces force boilers to use more fuel for the same thermal output.True

Insulation from deposits reduces heat transfer, requiring more combustion energy to reach target steam or water temperatures.

🧪 Case Study: 5 TPH Biomass Boiler with Soot Buildup

Symptoms:

Stack temperature rose from 180°C to 240°C

Fuel consumption increased by 12%

Combustion stable, but efficiency dropped

Intervention:

Conducted tube cleaning via soot blower

Removed ~1.5mm soot layer

Restored stack temp to 180°C

Recovered ~10.5% thermal efficiency

Annual fuel savings after cleaning: ~$28,000

🧹 Recommended Cleaning Practices

| Cleaning Method | Application | Frequency |

|---|---|---|

| Soot Blowing (manual/auto) | Removes ash and unburned carbon | Daily to weekly |

| High-pressure Water Jetting | Removes scale and residue | Monthly to quarterly |

| Chemical Descaling | Dissolves hard mineral scale | Quarterly to yearly |

| Mechanical Rod Cleaning | Tube brushing or scraping | Annually or during shutdown |

| Flue Path Vacuuming | Prevents fly ash recirculation | As needed |

Cleaning intervals depend on fuel type, ash content, and boiler run time.

📋 Signs That Indicate the Need for Cleaning

Rising stack temperature despite constant load

Decrease in steam output or pressure

Increase in fuel consumption per MWh

Visible black soot around burner or tubes

Alarms from flue gas analyzers or CEMS

Regular soot and scale cleaning improves heat exchanger performance and extends boiler lifespan.True

Clean surfaces reduce stress on tubes, prevent hot spots, and delay component failure.

🧮 Example Efficiency Recovery from Cleaning

| Fouling Thickness | Estimated Efficiency Loss | Savings After Cleaning (Fuel/Year) |

|---|---|---|

| 0.5 mm | ~3% | $5,000 – $12,000 |

| 1 mm | ~7% | $15,000 – $25,000 |

| 2 mm | ~12% | $30,000 – $50,000 |

Based on typical biomass fuel cost of $80/ton and usage of 2,500–4,000 tons/year.

Summary

Cleaning soot and scale from heat exchanger surfaces is essential for maintaining thermal efficiency in biomass boiler systems. Fouling acts as an invisible heat barrier that drives up fuel use, reduces steam output, and accelerates system wear. Regular maintenance—through soot blowing, chemical descaling, or manual brushing—can recover 5%–15% in lost efficiency and save tens of thousands of dollars per year. In the long run, a clean boiler isn’t just better for performance—it’s better for your budget. When it comes to heat exchange, clean metal saves money.

How Can Economizers and Air Preheaters Recover Waste Heat and Lower Operating Costs?

In biomass boiler systems, flue gas exits the combustion chamber at 180°C to 300°C or more, carrying with it massive amounts of unused thermal energy. Without recovery systems, this energy literally vanishes up the stack—wasting fuel and raising operating costs. Enter economizers and air preheaters, two proven technologies that capture this waste heat and reuse it within the system. The result? Lower fuel consumption, higher boiler efficiency, and faster payback.

Economizers and air preheaters recover waste heat from flue gases by transferring it to feedwater and combustion air, respectively. An economizer reduces the amount of fuel needed to heat water to steam by preheating the feedwater using exhaust gas heat, while an air preheater increases combustion efficiency by warming incoming air. Together, these devices can improve boiler efficiency by 5%–10% and cut fuel use by 8%–15%, significantly reducing operating costs. These savings can amount to tens of thousands of dollars annually depending on boiler size, runtime, and fuel type.

In biomass systems, economizers and preheaters are not upgrades—they are fuel-saving essentials.

Economizers and air preheaters can recover up to 20% of waste heat in biomass boiler systems.True

They capture thermal energy from flue gas and redirect it into feedwater and combustion air, improving efficiency and lowering fuel demand.

🔁 How Each System Works

| Device | Recovery Target | Resulting Benefit |

|---|---|---|

| Economizer | Preheats feedwater | Reduces fuel needed to generate steam |

| Air Preheater (APH) | Warms combustion air | Enhances fuel-air mixing, improves flame stability |

| Combined Use | Captures max flue heat | Boosts efficiency up to 10% |

Economizers operate at the boiler’s back-end, while air preheaters sit before the burner fan intake.

📉 Fuel Savings by Waste Heat Recovery

| Boiler Capacity (TPH) | Fuel Saved (%) | Annual Fuel Cost Reduction (USD) |

|---|---|---|

| 2 TPH | 6–8% | $12,000 – $18,000 |

| 5 TPH | 7–10% | $25,000 – $40,000 |

| 10 TPH | 8–12% | $50,000 – $80,000 |

| 20 TPH | 10–15% | $100,000 – $150,000 |

Based on wood chip biomass at $80/ton, 6,000 operating hours/year.

🧪 Case Study: 5 TPH Biomass Boiler with Flue Heat Recovery

Initial Conditions:

Flue gas temp: 240°C

Stack loss: ~18%

Feedwater temp: 65°C

After Installing Economizer + APH:

Feedwater temp increased to 95°C

Combustion air temp increased to 120°C

Flue gas temp reduced to 150°C

Fuel savings: 9.2%

Annual cost reduction: ~$32,000

Payback: < 2 years

📋 Performance Gains from Each Device

| System | Efficiency Gain (%) | Typical Temp Change |

|---|---|---|

| Economizer | 3–6% | +25–40°C to feedwater |

| Air Preheater | 2–4% | +30–70°C to air |

| Combined Effect | 5–10% | Flue temp drop ~80–120°C |

Each °C drop in stack temperature = ~0.3–0.5% gain in thermal efficiency.

Lowering flue gas temperature with heat recovery systems directly increases boiler thermal efficiency.True

Less heat wasted means more energy converted to useful steam, reducing fuel consumption.

📊 Economizer & APH Cost vs. Savings

| System | Installed Cost (USD) | Annual Savings (USD) | ROI Period |

|---|---|---|---|

| Economizer | $50,000 – $200,000 | $15,000 – $80,000 | 1–3 years |

| Air Preheater | $40,000 – $150,000 | $10,000 – $60,000 | 1–4 years |

| Combined | $90,000 – $350,000 | $25,000 – $130,000 | 1–3 years |

ROI improves with boiler size, fuel price, and run hours.

🔧 Design & Integration Considerations

| Factor | Design Impact |

|---|---|

| Flue Gas Composition | High ash or acid gases may corrode tubes |

| Fuel Type (e.g. wet chips) | May require corrosion-resistant alloys |

| Water Chemistry | Impacts scaling risk in economizer |

| APH Placement | Must match combustion fan location |

| Maintenance Access | Needs soot blowing ports or wash access |

For high-ash fuels, ASH FOULING CONTROL is crucial for reliability.

Summary

Economizers and air preheaters are core technologies for reducing waste and improving energy use in biomass boiler systems. By capturing flue gas heat and redirecting it to feedwater and combustion air, these devices improve efficiency by 5%–10% or more and deliver strong ROI through reduced fuel consumption. They also lower stack temperatures, reduce emissions, and stabilize combustion. In biomass-fired plants where margins matter, heat recovery isn’t an accessory—it’s a necessity. Investing in these systems ensures your boiler burns smarter, cleaner, and more cost-effectively for years to come.

What Role Does Regular Maintenance and Inspection Play in Preventing Performance Loss?

Biomass boiler systems operate under high thermal, mechanical, and chemical stress. From ash buildup in heat exchangers to corrosion in feedwater lines and sensor drift in control systems, every operating hour exposes the system to gradual wear and fouling. Without regular maintenance and inspection, small inefficiencies compound into serious performance loss, higher fuel usage, unexpected shutdowns, and expensive repairs. Preventive maintenance ensures the system stays clean, calibrated, and compliant—delivering maximum thermal output at minimum cost.

Regular maintenance and inspection prevent performance loss in biomass boilers by addressing fouling, mechanical wear, fuel feeding inconsistencies, sensor drift, and ash buildup before they escalate into system failures. Scheduled cleaning, calibration, lubrication, and visual checks maintain combustion stability, protect thermal efficiency, and ensure emissions compliance. Facilities that implement preventive maintenance can maintain up to 95% of original system performance, while poorly maintained systems can lose 10%–25% efficiency within a few years.

If efficiency is the goal, maintenance is the guarantee.

Preventive maintenance keeps biomass boiler systems operating near peak efficiency and reduces unplanned downtime.True

Scheduled cleaning, inspection, and part servicing prevent buildup and breakdowns that degrade performance and increase fuel use.

🔁 Key Areas Affected by Neglected Maintenance

| System Component | Risk When Unmaintained | Impact on Performance |

|---|---|---|

| Heat Exchanger Surfaces | Soot/scale buildup | 5–15% drop in heat transfer |

| Fuel Feeding System | Blockages, belt wear | Inconsistent combustion |

| Burner & Airflow Fans | Misalignment, dust clogging | Unstable flame, excess air |

| Ash Handling System | Overflow, motor jamming | Shutdowns, operator delays |

| Sensors (O₂, temp, pressure) | Drift, failure | Incorrect air-fuel ratio |

| Water Treatment System | Scaling, corrosion | Tube damage, poor efficiency |

Even minor fouling or miscalibration can lead to 5%–10% efficiency loss and unexpected downtime.

🧪 Case Study: Maintenance Impact on a 4 TPH Biomass Boiler

Situation:

Annual steam production dropped by 12%

Fuel consumption rose 14%

Operators noticed longer warm-up time and increased ash

Inspection Findings:

Economizer blocked by soot

Fuel feeder chain stretched

O₂ sensor out of calibration

Ash bin overflowing

After Full Maintenance:

Steam output restored

Fuel savings: ~$24,000/year

Downtime reduced by 80%

ROI of maintenance overhaul: <6 months

Ignoring small maintenance issues in biomass boilers leads to cascading performance losses.True

Blocked exchangers, clogged feeders, and miscalibrated sensors amplify each other’s impact on system efficiency.

🔍 Recommended Maintenance and Inspection Schedule

| Maintenance Activity | Frequency | Method or Tool |

|---|---|---|

| Soot blowing (auto/manual) | Daily to weekly | Steam/air lances |

| Tube visual inspection | Monthly | Boroscope or manual check |

| Fan & blower service | Monthly to quarterly | Clean blades, check motor |

| Sensor calibration (O₂, temp) | Monthly | Handheld meter or CEMS |

| Fuel conveyor alignment check | Weekly | Visual + load balance |

| Ash bin level monitoring | Daily | Manual or level switch |

| PLC & alarm system test | Quarterly | Simulate fault triggers |

| Water chemistry test | Daily to weekly | pH, TDS, hardness kits |

A preventive plan with daily, weekly, monthly, and annual tasks minimizes long-term performance erosion.

📉 Performance Loss from Deferred Maintenance

| Delay Period | Expected Efficiency Loss (%) | Downtime Risk |

|---|---|---|

| 3–6 months | 2–5% | Low |

| 6–12 months | 5–10% | Moderate |

| 1–2 years | 10–20% | High |

| 2+ years | 15–25%+ | Very high |

Performance degradation accelerates over time without maintenance—and recovery becomes more costly.

📋 Maintenance ROI vs. Repair Cost

| Maintenance Type | Annual Cost (USD) | Prevented Issues | Savings Value |

|---|---|---|---|

| Routine tube cleaning | $10,000 – $30,000 | Efficiency loss, overheating | $20,000+/year |

| Fan motor service | $5,000 – $10,000 | Vibration, poor airflow, shutdowns | $15,000+ |

| Sensor calibration | $2,000 – $6,000 | Incorrect AFR, emissions violations | $10,000 – $30,000 |

| Ash handling upkeep | $5,000 – $12,000 | Blockages, manual labor delays | $8,000 – $20,000 |

Regular maintenance offers 3x to 10x return on investment by avoiding system underperformance and downtime.

Summary

Regular maintenance and inspection are non-negotiable for biomass boiler systems seeking optimal thermal efficiency, fuel economy, and equipment longevity. From soot blowing to sensor calibration, proactive upkeep ensures your system operates like it was designed to—not 10% slower and 15% more costly. Facilities that commit to a structured maintenance plan experience fewer failures, higher efficiency, and reduced fuel costs, often saving thousands annually. In biomass combustion, maintenance isn’t a cost—it’s your best insurance against performance loss.

How Does Fuel Quality and Preheating Affect Combustion Stability and Emissions?

In biomass combustion systems, fuel isn’t just a heat source—it’s the foundation of combustion behavior. Fuel with inconsistent size, high moisture content, or low energy value disrupts flame stability, increases smoke and unburned gases, and accelerates fouling. Poor-quality biomass leads to inefficient burns, volatile emissions, and erratic load control. However, when fuel is well-prepared and preheated—whether naturally (via storage) or through mechanical or thermal aids—it burns cleaner, more completely, and more efficiently. That’s why fuel quality and preheating are critical levers in ensuring combustion stability and environmental compliance.

Fuel quality and preheating affect combustion stability and emissions by determining how consistently, efficiently, and completely biomass burns. High-moisture or variable fuels reduce flame temperature and increase incomplete combustion, leading to higher carbon monoxide (CO), unburned hydrocarbons, soot, and particulate matter (PM). Preheating the fuel—by drying or using warm air—improves ignition, maintains stable flame propagation, and reduces emissions. Consistent particle size, low ash content, and controlled moisture (ideally below 20%) are key to achieving stable combustion and low pollutant output in biomass boilers.

When the fuel is right and preheated, combustion is clean, stable, and efficient—but when it isn’t, costs rise and emissions spike.

Fuel quality and moisture content are key factors influencing biomass combustion stability and emission performance.True

Inconsistent or wet fuels result in unstable flames, higher unburned gases, and increased emissions.

🌿 Fuel Quality Parameters That Impact Combustion

| Parameter | Ideal Range | Effect if Poor Quality |

|---|---|---|

| Moisture Content | < 20% (target 10–15%) | Delayed ignition, low flame temp, high CO |

| Particle Size Uniformity | 10–50 mm chips or ≤10 mm pellets | Unstable feed rate, fluctuating burn |

| Bulk Density | ≥ 180 kg/m³ (pellets ~650) | Affects feed system consistency |

| Ash Content | < 3–4% for most fuels | Fouling, slagging, high PM |

| Volatile Matter | 60–80% | Supports stable flame if balanced |

| Calorific Value | 15–18 MJ/kg (dry) | Influences boiler capacity/output |

Biomass with moisture >30% may reduce combustion efficiency by 10% or more, raising fuel consumption and emissions.

🔥 Effects of Preheating Biomass Fuel

| Preheating Method | What It Improves | Resulting Benefit |

|---|---|---|

| Mechanical Drying (rotary drum, belt dryer) | Lowers moisture to <15% | Stable combustion, lower CO |

| Combustion Air Preheating | Raises flame temp by 50–100°C | Enhances ignition and efficiency |

| Warm Storage (covered sheds) | Uses ambient heat to reduce wetness | Reduces drying load in furnace |

| Indirect Heat Recovery | Uses economizer heat to dry fuel | Improves boiler thermal efficiency |

Preheating helps ensure steady flame propagation, even with marginal fuels.

Preheating biomass fuel reduces moisture content and improves combustion stability and flame quality.True

Dry fuel ignites more quickly and burns more evenly, lowering carbon monoxide and particulate emissions.

📉 Impact of Moisture on Combustion Efficiency and Emissions

| Moisture Level | Efficiency Drop | CO/PM Emissions Increase | Fuel Usage Increase |

|---|---|---|---|

| 10–15% | Baseline | Normal | — |

| 20–25% | -3% to -5% | +15–20% | +5–8% |

| 30–35% | -6% to -9% | +30–50% | +10–12% |

| >40% | -10%+ | +70%+ | +15–20% |

For every 10% rise in moisture, expect ~2–4% efficiency loss and significantly higher CO and PM levels.

🧪 Case Study: Fuel Drying in a 3 TPH Biomass Boiler

Before Drying:

Moisture content: 35%

Efficiency: 70%

CO: 350 ppm

Fuel consumption: 3,800 tons/year

After Pre-Drying to 15%:

Efficiency: 81%

CO: 110 ppm

Fuel consumption: 3,200 tons/year

Fuel savings: 600 tons/year (~$48,000)

Emissions compliance passed without retrofitting

📋 Best Practices for Managing Fuel Quality

| Practice | Resulting Benefit |

|---|---|

| Use screened, dry wood chips | Improves flow and combustion balance |

| Store fuel in dry, covered area | Reduces moisture pickup |

| Install moisture meters | Enables fuel batch sorting |

| Blend fuels for consistency | Smooths volatility, maintains stable flame |

| Integrate fuel pre-dryer | Maximizes value from high-moisture sources |

Dry, uniform biomass fuel leads to cleaner combustion and lower regulatory risk.True

Lower moisture and consistent size reduce unburned emissions, improve burner stability, and reduce fouling.

Summary

Fuel quality and preheating are foundational to efficient, clean biomass combustion. High moisture, variable particle sizes, and inconsistent energy values degrade flame stability, lower efficiency, and increase emissions. Preheating through drying systems or combustion air warming significantly improves ignition, flame uniformity, and pollutant reduction. Facilities that manage fuel quality and drying properly see lower fuel use, stable operation, and cleaner stack emissions. In every successful biomass boiler, good fuel is half the combustion—and preheating unlocks its full value.

How Can Automation and Real-Time Monitoring Improve Long-Term Cost Control?

In modern biomass boiler systems, manual oversight alone isn’t enough to ensure peak performance. Variations in fuel quality, load demand, and combustion conditions can shift efficiency and emissions in real time. Without automated responses and continuous data insights, these fluctuations lead to higher fuel use, increased wear, missed efficiency opportunities, and regulatory risks. That’s where automation and real-time monitoring come in. These technologies enable proactive control, reducing fuel waste, improving uptime, and unlocking long-term cost savings through smarter operations.

Automation and real-time monitoring improve long-term cost control by optimizing combustion efficiency, preventing unplanned downtime, reducing labor costs, and enabling predictive maintenance. Automation systems (like PLCs, DCS, and SCADA) adjust air-to-fuel ratios, fuel feed rates, and ash removal in response to real-time sensor feedback. Monitoring tools track key parameters—flue gas temperature, oxygen levels, steam output, and equipment health—so operators can respond instantly or program automatic corrections. Over time, this reduces fuel consumption by 5–15%, extends equipment life, lowers emissions penalties, and minimizes maintenance surprises.

Without automation, you’re driving a boiler blind. With it, you’re saving fuel, avoiding breakdowns, and staying compliant.

Real-time monitoring and automation reduce operating costs by maintaining optimal efficiency and minimizing downtime.True

Sensors and control systems detect performance changes instantly, enabling automatic adjustments that reduce waste and avoid costly failures.

🔁 Core Automation Functions and Cost Benefits

| Function | Automation Role | Cost Control Impact |

|---|---|---|

| Combustion Control (O₂ trim) | Balances air and fuel feed | 5–10% fuel savings |

| Fuel Feed Regulation | Matches feed to steam demand | Prevents overburn, fuel waste |

| Soot Blower Activation | Auto-cleaning based on ΔT or runtime | Maintains efficiency, reduces labor |

| Ash Handling Automation | Avoids overflow and blockages | Prevents shutdown, lowers manpower |

| Boiler Load Modulation | Matches capacity to demand | Avoids short-cycling and fuel loss |

| Safety Alarms & Interlocks | Prevents unsafe operation | Avoids damage, reduces liability |

Automating these tasks ensures that system behavior adjusts as conditions change, rather than reacting late or inconsistently.

📉 Long-Term Operating Cost Comparison

| Operation Type | Manual/Minimal Automation | Full Automation & Monitoring |

|---|---|---|

| Fuel Use | High variability (+8–15%) | Optimized (baseline or better) |

| Downtime | 3–6% unplanned/year | <1% with predictive tools |

| Labor Intensity | High | Lower (fewer reactive tasks) |

| Emissions Compliance | Manual testing | Real-time assurance |

| Maintenance Costs | Reactive, high | Predictive, lower |

| Data Insight | Paper logs | Real-time dashboards |

Facilities using real-time analytics and auto-tuning report 10–25% reduction in annual OPEX.

🧪 Case Study: 5 TPH Biomass Boiler with SCADA + PLC Upgrade

Before Automation:

Stack O₂ fluctuated 6–9%

Frequent operator interventions

5 unplanned shutdowns/year

Fuel use: 4,200 tons/year

After Automation:

Stack O₂ maintained at 3.5% ± 0.2%

No unplanned shutdowns in 12 months

Fuel use: 3,750 tons/year

Fuel savings: ~$36,000/year

Downtime loss avoided: ~$18,000/year

ROI on system: <1.8 years

📋 Key Monitoring Parameters for Real-Time Cost Control

| Parameter | Sensor Type/Source | Cost-Linked Insight |

|---|---|---|

| Flue Gas Temperature | Stack thermocouple | Detects fouling or efficiency loss |

| Oxygen (O₂) | Zirconia sensor or CEMS | Adjusts air-to-fuel ratio |

| Steam Output (TPH) | Flow transmitter | Tracks demand/load response |

| Combustion Air Flow | Pitot or mass flow meter | Balances burner operation |

| Feedwater Temperature | RTD in economizer outlet | Indicates recovery system health |

| Motor Vibration | Vibration sensors | Predicts bearing or fan failure |

| Differential Pressure | Baghouse or economizer | Flags clogging or soot buildup |

Real-time monitoring of temperature, oxygen, and pressure improves combustion tuning and early fault detection.True

These parameters directly affect fuel efficiency, heat recovery, and system integrity.

📈 Software and Tools That Support Monitoring

| Tool/System | Functionality | Benefit |

|---|---|---|

| SCADA (Supervisory Control) | System-wide visualization, trending | Centralized decision-making |

| PLC (Programmable Logic Controller) | Automated control loops | Fast reaction, minimizes drift |

| CEMS (Continuous Emissions Monitor) | Real-time emissions reporting | Ensures compliance, avoids fines |

| Data Historian | Stores years of data for trends | Predictive modeling, audits |

| Predictive Maintenance Software | Alerts before component failure | Lowers long-term maintenance costs |

Integration enables automated tuning, real-time alerts, and visual KPIs that guide operators and managers alike.

Summary

Automation and real-time monitoring aren’t just conveniences in biomass boiler operations—they are strategic tools for cost control, risk reduction, and efficiency assurance. By continuously tracking and adjusting air-fuel ratios, combustion dynamics, and system health, automated systems keep boilers operating at peak performance. The result is less fuel wasted, fewer breakdowns, lower emissions, and more informed decisions. For plant managers and engineers, investing in automation means trading guesswork for precision—and cutting costs with every clean, optimized burn. In the long run, smart control is smart economics.

🔍 Conclusion

Optimizing an industrial oil-fired boiler is about balancing combustion, heat recovery, maintenance, and monitoring. By focusing on fuel efficiency, flue gas management, and predictive diagnostics, companies can significantly reduce fuel costs, improve emissions performance, and ensure stable operation. With proper optimization, your boiler becomes not just a heat source—but a high-efficiency, low-cost energy solution.

📞 Contact Us

💡 Need expert help optimizing your oil-fired boiler system? Our engineers provide combustion tuning, maintenance planning, and energy efficiency consulting tailored to industrial oil-fired boilers.

🔹 Contact us today and unlock the full cost-saving potential of your oil-fired boiler system! 🛢🔥📉

FAQ

What are the best ways to optimize an industrial oil-fired boiler?

To maximize efficiency and minimize costs:

Perform regular burner tuning

Maintain correct air-to-fuel ratio

Install oxygen trim systems

Clean heat exchanger surfaces and remove soot

Use economizers for heat recovery

Schedule routine inspections and maintenance

How does combustion control reduce operating costs?

Efficient combustion ensures complete fuel burn and reduces waste. Installing oxygen trim or flue gas analyzers enables real-time adjustment of the air-fuel mix, improving combustion efficiency by 3–5% and lowering fuel use.

Why is burner tuning critical for oil-fired boilers?

Oil burners require periodic adjustment to prevent incomplete combustion and minimize unburnt fuel, smoke, and soot. A well-tuned burner maintains flame stability, reduces emissions, and improves heat output per gallon of fuel.

Can heat recovery systems improve efficiency in oil-fired boilers?

Yes. Economizers recover heat from flue gases to preheat feedwater, increasing efficiency by 5–8%. Condensing heat exchangers can further boost savings, especially in lower-temperature return systems.

What maintenance practices reduce long-term operating costs?

Remove soot buildup from tubes to restore heat transfer

Check and replace nozzles, gaskets, and filters

Monitor stack temperature and flue gas composition

Inspect refractory linings and combustion chamber integrity

Proactive maintenance extends equipment life and ensures consistent efficiency.

References

Boiler Efficiency Improvement Guide – https://www.energy.gov

Combustion Optimization for Oil Burners – https://www.sciencedirect.com

Flue Gas and Oxygen Trim Controls – https://www.researchgate.net

Oil-Fired Boiler Maintenance Best Practices – https://www.epa.gov

Economizers and Heat Recovery in Boilers – https://www.bioenergyconsult.com

Air-to-Fuel Ratio Tuning in Industrial Systems – https://www.mdpi.com

Boiler Performance Monitoring Tools – https://www.automation.com

Efficiency Trends in Oil-Fired Boilers – https://www.iea.org

Industrial Boiler TCO Reduction Strategies – https://www.energysavingtrust.org.uk

ASME Guidelines on Boiler Efficiency – https://www.asme.org